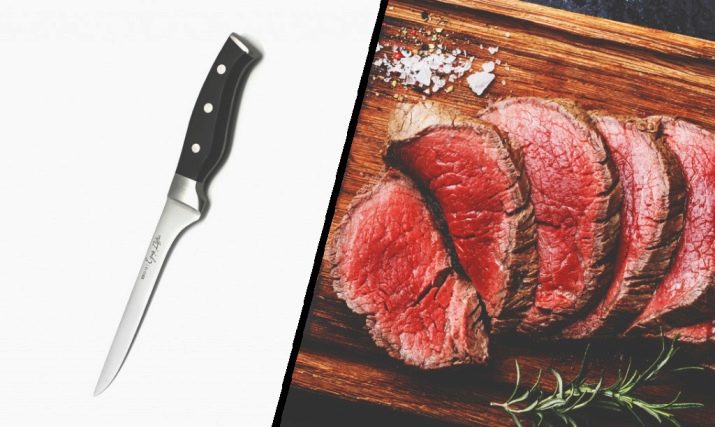

Today, many of the old habit of cooking uses one knife to cut different products. This is the wrong approach. Various special knives due to the fact that they have an unusual shape and structure can greatly simplify this process. One of the most important and necessary in the kitchen should be called a boning knife. A similar professional knife is used to carry out the separation of bones and meat.

Features

A boning knife will be the main tool to separate the meat from the bones. It was his use that determined a certain geometry and shape of the handle. If we talk about European knives, they can be distinguished from others by a narrow long blade, greatly expanding at the handle. The length of the blade, curved in the form of an arc, can reach 20 centimeters. This solution makes it very easy to separate the meat from the bones. In addition, the considered category of knives can perfectly cope with tendons and strong fibers.

When creating such a solution, forged or rolled molybdenum-vanadium steel is usually used. A high percentage of carbon makes the blade hard, molybdenum further strengthens it, chrome allows excellent corrosion resistance and increases wear resistance, and vanadium makes it more elastic. Such solutions are always sharp, do not oxidize and do not fade. This is especially important, because this knife is in contact with the juice of meat, which is a chemically active substance. The cutting edge should be tempered somewhere at the level of 53-56 HRC, because this type of knife needs permanent dressing with musat. If the hardness is higher, then for this it is better to use a smooth type of garbage.True, this increases the chance that a chip will appear on the blade.

Care should be taken with the handle. It should be as ergonomic and extremely reliable.

Typically, such parts of knives are made of thermoplastic, wood or mikarta. Handles made of metal are a rarity. The reason is that they make the knife heavier and your hand will get tired faster. A good grip should have a mini-guard and sometimes a small bolster. It makes the knife more balanced, and the guard will not allow the hand to slip on the blade during use.

What is it needed for?

A boning knife is used when cutting carcasses or cutting large pieces of meat. It is also used to separate veins and meat from bones, and when it is required to separate the skin from a piece of meat. It will be an ideal solution in cases where it is necessary to separate the skin from the meat of fish.

Kinds

If we talk about the types of boning knives, it is necessary to indicate that there is no universal classification that would allow a clear distinction to be made between boning, veneering and some other types of knives. The most common classification option is as follows:

- boning;

- for trimming;

- billhook;

- ax.

That is, everything will depend on the goal that is set for the butcher or cook.

If it comes to working with a large piece of meat, then in this case it is better to use an ax knifethat will allow you to quickly and easily cut it into smaller parts. If we are talking about choppers, then it is usually the standard solution for Chinese cooks. It looks like an ax in some ways, but has a different pen structure, and its dimensions are slightly smaller.

When we talk about separating bones from meat, a deboning knife comes into play. And more precisely, to separate the fillet from the bones. If the meat is sinewy and has a lot of fibers, then it would be better to use a trimming knife, which will quickly remove all unnecessary and clean the meat.

In general, the boning option is universal. With it, you can do almost anything, with not very large pieces of meat. This is possible because it has a flexible blade that bends perfectly and allows you to cut even the smallest meat pieces from the bones.

There is a second classification of the devices in question. According to her, knives are divided into:

- professional;

- the kitchen.

Kitchen cutting solutions include amateur tools that are used exclusively at home. Professional options include those that are used in factories for the industrial cutting of meat carcasses. An example is the same saw for cutting meat carcasses. But this does not mean that any of these knives cannot be used at home. But amateur or kitchen models are not suitable for the production of meat trimming.

Another classification is sometimes considered. According to her, boning knives are divided into processing solutions:

- carcass of meat;

- bakery products;

- cheese;

- vegetables;

- birds.

Manufacturers Overview

We turn to the manufacturers of boning models, whose products are of high quality. According to many, the best boning knives produces Brazilian company Tramontina, founded in 1911 in the city of Carlos Barbosa. Knives of this company received a lot of awards at various competitions, and are considered one of the most effective for cutting meat. They are distinguished by high strength and the ability to maintain sharpness with intensive use.

Speaking about boning options of the manufacturer, it can be added that their blade is made of high quality stainless steel and has a thickness of 2 millimeters. They are equipped with a beautiful and very comfortable handle made of polypropylene. This determines its longevity. It also has a special coating against bacteria, which prevents them from spreading if they get on the handle.

Buyers note that products from Tramontina really stay sharp for a long time, even if they are exploited very often.The handle is convenient to take, and it is very light. Therefore, the hand does not get tired even when working with a large amount of meat.

The working blade has a high quality polishing, which allows it not to darken as it is applied. By the way, it is made in a V-shape to maximize the accuracy of cutting.

Germany has achieved great success in the production of boning knives. One of the most famous German knife manufacturers, Eicker company, located in the city of Solingen, for more than 80 years produces high-quality boning and other types of knives. They are made of durable stainless steel with a high admixture of chrome. In addition, vanadium and molybdenum can be found in its composition, which prevent the destruction of the blade. Their use also makes it possible to get the sharpest knives, which do not blunt due to constant use.

All products from Eicker have a comfortable handle made of rubber and nylon, as well as fiberglass. This allows us to guarantee not only the ease of use of such a knife, but also its strength. Even when falling from a great height, such models retain their hardness and properties.

German products are also popular in this segment. Giesser. Boning knives of this company are of the highest quality and amazing hardness with a rate of 56 HRC. The manufacturer creates products from chrome-molybdenum steel, and processes them with a special antibacterial silver coating. This allows you to successfully resist the occurrence of fungi, mold and germs.

Each model manufactured under the Giesser brand has a special number, which allows you to quickly repair or replace a certain part of the knife if necessary.

It is important that the manufacturer gives a lifetime guarantee on the produced models, which makes them an almost ideal option not only for a professional cook, but also for an ordinary housewife.

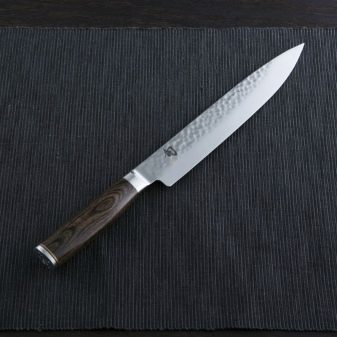

Quality knives of this type can also provide Japan. The manufacturers of this country are able to make high-quality knives, which is confirmed historically. And boning knives are no exception. For example, knives Japanese manufacturer KAI SHUN made of damask steel of the highest strength. The knife blades are sharpened on both sides, which will ensure the deep penetration of the blade into the meat. The handle of boning knives KAI SHUN is made of elite ebony, which is coated with a special coating. It prevents rotting and prevents insects from damaging it. Knives manufacturer have increased strength. By the way, the handle also perfectly resists moisture, so that it does not crack.

All boning models are equipped with a bolster located between the blade and the handle, which allows food residues not to accumulate at the junction of the blade and handle. This provides a high level of safety during the execution of meat cutting. At the tip of the handle is a “heel” made of steel. It serves to protect the knife from deformation during a fall or any accidental impacts. Naturally, this will extend the life of the product, making it almost invulnerable to mechanical damage.

I also want to say about the German manufacturer F. Dick. This company has been producing high-quality knives, including boning knives, for more than 230 years. F. Dick products are valued primarily for their ergonomics and highest quality steel. This company has good reviews also because experience allows it to develop innovative kitchen tools, which will be appreciated not only by a housewife, but also by any professional chef. No wonder she is the main supplier of knives for many enterprises, not only in Germany but also in other European countries.

Great success in creating knives, including boning and veneering, has achieved Polkars companylocated in Poland. It also manufactures a wide range of cutting tools for the meat industry.Including we are talking about veneering and boning models. Blades of models from Polkars They have excellent hardness and are made of chromed molybdenum steel. A knife handle made of wood or special anti-slip plastic.

As you can see, it is quite possible to find a large number of manufacturers from different countries on the market, whose products are really high-quality, and have already been tested by time.

How to choose?

Before buying a set of knives or a specific boning knife, you should study all the subtleties of the desired purchase. And the following tips will help you do this.

Decide on the category of knife in advance. That is, you need to understand which knife is required: a professional version or intended for widespread use in everyday life. It is clear that the cost of both solutions will be different. On the other hand, among professional models there are significantly more quality options that, in a few decades, will fulfill their functions as if they were bought yesterday. But still, even for such models, it will not be superfluous to have sharpening tools at hand.

In addition, when purchasing a knife, you should pay attention to the composition of the alloy and quality in general. After all, sharpening one material according to a certain scheme may not bring results if the knife is used for other purposes. It can generally ruin a knife blade. The handle is also very important. Many people do not pay attention to it when buying a knife, which is a big mistake. But not only comfort in work and convenience depends on it, but also safety of use.

The best solution is the option when the handle is, as it were, a continuation of the blade. In this case, the possibility of the blade falling out of the handle is completely excluded.

Another point is ease of use. A person who will use a boning knife should take it in their hands before buying to understand how convenient it will be to use it. The degree of sharpness and sharpening is also important. The quality of the product, as well as the durability of its use, depends on them.

And the last nuance that should not be neglected is reviews about the manufacturer. It’s better to overpay a little, but to get a well-known and high-quality solution than to buy advertised models from unknown manufacturers. Saving on a boning knife in 95% of cases leads to the fact that he quickly becomes worthless, and he needs a replacement. Therefore, it is better not to save.

In general, guided by these tips, you can quite easily get a high-quality boning knife, which will serve excellently for a long time.

For an overview of Eicker boning knives, see the next video.