To this day, among knives designed both for kitchen and hunting, and for throwing, the most durable, reliable and durable are still products made by forging. Most of the tools are performed by handmade masters, taking into account the requirements and wishes of the customer. This makes it possible to purchase exactly the thing that will last a long time and in the full sense will become irreplaceable.

Pros and cons of the forged product

You can understand that the knife is forged and made according to all the rules of blacksmithing, by the stamp on the blade, which is applied by the impact method.

The advantages of a forged homemade tool:

- the product is durable because it has high strength characteristics;

- the blade remains sharp for a long time, due to the use of special technology;

- strength is one of the parameters determining the quality, it is due to the fact that the knife is forged from solid steel and has no seams, this eliminates breaking of the blade and increases resistance to heavy loads;

- forged kitchen knives have a unique design, as a rule, are made in a single copy, therefore they are of special value as a work of craft art.

Such products also have their disadvantages, which are relative. These include:

- high cost, due to manual work and the implementation of individual customer ideas;

- heavy weight - such specimens are heavy, and after ordinary kitchen knives it will be uncomfortable to use them for some time.

Not too critical flaws, given that the people ordering them are well aware of such nuances.

Application area

Each forged tool should be selected according to the established characteristics, based on the purpose for which it is purchased.

According to their purpose, cast seamless knives can be divided into several groups.

- Combat, more precisely, throwingwhich are in great demand, the main requirements for them are small thickness, lightness and perfect balance. The same category includes hiking, tourist and fishing knives, folding forged products.

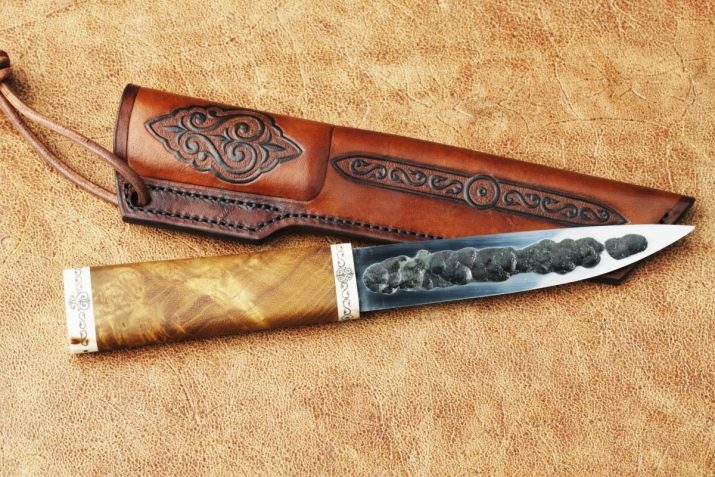

- Hunting bladescharacterized by medium dimensions with a small handle and a large blade. They are most often decorated with various images or supplemented with elements necessary for hunting.

- Household, household, multifunctional products used in the kitchen. They are used for cutting meat, vegetables, finished products. Due to the high price, as a rule, chefs of elite restaurants work with them, but sometimes they are also purchased for home cooking. A feature of such a knife is the proportional size of the handle and blade, as well as a large length, compared with hunting.

As for combat knives as weapons, this is a separate category, especially since such a tool needs permission.

For camping and hunting accessories designed as gifts, molding is often used to complement the forging to decorate the handle with a pommel or guards.

An important requirement for a kitchen knife blade is its sharpness, small thickness, and the absence of auxiliary elements. The product can be universal and suitable for cutting a variety of products, however, there are also highly specialized tools that are used specifically for the finest cutting of meat or fish.

Forging process

Thanks to the forging method, an advantageous combination of the quality of the tool and its excellent appearance is achieved.

This is a multi-stage technique. Product manufacturing includes four key points.

- First, the appropriate material is selected., usually it is carbon tool steel obtained by alloying with vanadium, silicon, chromium and other elements. A sketch of the product is also made.

- The next stage is incandescent. Steel is heated in the furnace, after which it is forged until the initial workpiece is created. This is a roughing, then when cooling it tends to decrease one and a half times.

- Final form the blade takes during finishing forging, at this time the blade is sharpened, complemented by drawings and ornaments at the request of the customer. After completing the work, making any transformations will not work.

- In the end, to gain strength, the knife is temperedby immersing in cold water.

In fact, only a perfect blade is required from the blacksmith, and in most cases the shoe remains unprocessed so as not to violate the integrity of the product. Therefore, the dull side of the blade is rarely supplemented by anything.

Beautiful forged kitchen knives

For a professional chef, and for an ordinary housewife, if she is not afraid of the weight of the forged accessories, the originally made knife for the kitchen will be a wonderful gift, and most importantly, a truly sharp and durable, practically “unkillable” tool.

You can stop your choice on the following unusual knives.

- Japanese kitchen knife "Kuritsuke" from forged steel with a handle from stabilized maple burl and elk horn. Such a product weighs only 235 g, despite its high strength. The total length is 330 mm, the blade is 210 mm with a butt width of 2.4 mm and a blade width of 35 mm.

- All-metal super-knife handmade "Chef" Damascus steel for the kitchen with a handle from a particularly valuable species - tropical wenge wood. The length of the knife is 285 cm, the blade is 160 cm. According to reviews - an excellent high-quality forged product.

- Damask steel fillet knife with a handle of black (mahogany) wood with an unusual pattern on the blade. The length of the product is 325 mm, the length of the blade is 205 mm with a width of 26 mm and a thickness of only 1 mm. The width of the handle is 30 mm. In addition there is a case made of genuine leather.

- Another damask steel knife with a narrow and thin blade is made using hornbeam wood and cupronickel inserts. It has a length of 340 mm, a blade length of 205 mm with a width of 18 mm and a blade thickness of 2.4 mm. Stick width 30 mm.

Since the handle of kitchen tools is not customary to decorate with embossed decor elements, a knife with forging marks on the blunt side of the blade can become an interesting and unusual option for a presentation. It looks beautiful and exotic.

About the features of forged kitchen knives, see the next video.