Soap making is a popular activity that can compete with traditional hobbies such as knitting and sewing. This hobby gains more and more popularity every year, not only due to the fascinating and creative process, but also because of the desire of housewives to use only high-quality hygiene products for skin care of the face and body. The basis for these products is a soap base. This product can be purchased in specialized stores of several types. Before starting the production of unusual products, one must carefully study the technology of their manufacture and the rules for the safe execution of work.

Description

Soap base is a necessary component that is used for the manufacture of soap and various cosmetics both at home and on an industrial scale. The main components of the classic soap base:

- water;

- glycerol;

- palm of sodium;

- tetrasodium ethidronate;

- sorbitol;

- organic acids;

- sodium chloride.

This composition can be slightly changed at the request of the manufacturer due to the need to add additional ingredients to improve the quality of the final product. The properties of additional components and their amount have a direct effect on the type of soap base. The most common additional components are the following items:

- stearic acid;

- propylene glycol;

- lauric acid;

- sodium laureth sulfate;

- sodium laurate.

Kinds

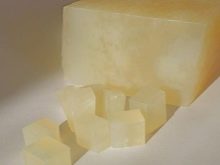

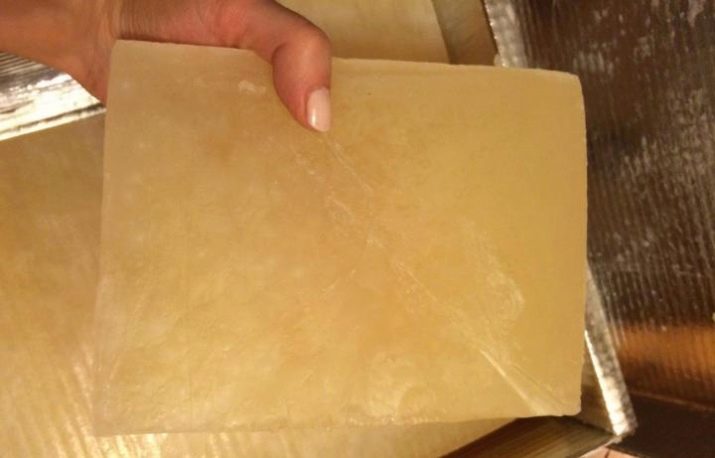

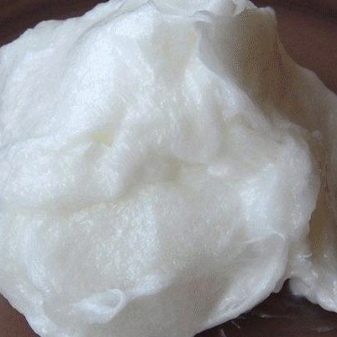

In specialized stores you can see several types of soap bases. Depending on the appearance, the base is transparent and white.These products differ from each other only in that there is titanium dioxide (dioxide) in an opaque base. You can add this component to a colorless product at home, by combining a special powder with a melted mass. Manufacturers produce several types of base:

- organic

- cream;

- liquid.

The organic base for soap is a popular and expensive product that enjoys a high level of demand and is sold in specialized stores with natural goods. The natural product does not contain brightening dyes and chemical components and consists of the following elements:

- water;

- glycerol;

- sorbitol;

- salts of fatty acids.

Beauticians recommend this tool to people suffering from allergic rashes and skin diseases.

The main advantages of the natural product are the absence of sodium laureth sulfates in the composition of propylene glycols. As you know, they have a negative effect on the skin and mucous membrane.

Creamy (jelly-like) soap base is a unique tool that is used to create mousses and foam for washing. The main feature of this product is preservation of soft and airy consistency throughout the entire period of use. The cream base lacks thickeners and stearic acids. This product consists of water, cocoyl sodium, glyceryl, sorbitol, stearic acid and sodium chlorine.

For the manufacture of DIY cosmetics on the basis of a cream base, it is enough to simply combine it with the necessary ingredients. If you add a small amount of air mass to the composition in the manufacture of ordinary soap, the final product will be softer, more gentle and much better than the store.

Beauticians recommend paying attention to a natural creamy base, which includes milk.

Handicrafts, which include a dairy product, have short implementation period and special storage conditions.

For the manufacture of liquid soap, shampoo or shower gel, manufacturers produce a liquid soap base. This product contains the same components as a solid base. The main difference between a liquid product is the presence of fatty acids in the composition of sodium salts, and not potassium. When using a liquid product, it is enough to simply add all the planned components to it.

The composition of the liquid base:

- water;

- potassium cocoate;

- potassium oleate;

- glycerol;

- benzyl alcohol.

You can even replace the soap base with simple children's soap, which does not contain chemical components and is anti-allergic. The advantage is a quick connection with essential oils. Disadvantages - a long period of melting, the presence of a specific smell.

Selection rules

Before starting the manufacture of home soap, experts recommend choosing the right base. The universal substance for soap is a transparent base that can be used both for the manufacture of cosmetic products and for the production of gift souvenirs. Decorative ingredients will be given to the soap with bright ingredients that will look spectacular in a transparent product. These components can be spangles, parts of plants and inflorescences, as well as the peel of citrus fruits. Professional soap makers inside the soap make congratulatory inscriptions and interesting drawings.

White substance has a lower price and is used to make the product for daily use. The white base can be used to create any shapes, animals, birds, sweets, fruits and decor items. Often home craftsmen order soap bouquets and toys. Natural components are chosen by people who pay increased attention to their health or have problem skin. You can buy a natural substance both in solid form, and in liquid and creamy form.

When choosing this product, you need to pay attention to the price range and country of manufacture. Quality products cannot have a low price.

Experienced soap makers recommend purchasing an English or German soap base, which melts easily and quickly, and also does not have a specific smell and, when combined with additional ingredients, acquires a uniform structure.

It’s very easy to make patterns and inscriptions on a German base that hardens for quite some time.

Home-made

Soap-making is a fascinating and uncomplicated process that can be carried out at home, and the recipe can be found in specialized literature. Before starting work, it is necessary to purchase a glass or stainless heat-resistant container of the required volume for cooking. Experts do not recommend the use of dishes made of aluminum, copper and plasticwhich, when heated, will release hazardous elements.

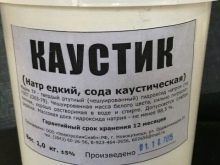

When working with chemical components tight-fitting clothing should be worn to cover skin, rubber gloves, a respirator, goggles and a rubber headgear as much as possible. To measure the temperature, you must first purchase a thermometer. All tools and molds must be clean and dry, and the working surface is even. A prerequisite during soap making is the presence of a working ventilation system in the working room.

Ingredients for making a soap base:

- distilled water;

- base essential oils;

- caustic soda;

- glycerol;

- overweight.

Experts recommend using a special program for home soap making - a soap calculator that will help determine the exact amount of necessary components. There are two ways to make soap yourself:

- cold

- hot.

The main stages of cold soap making:

- adding alkali powder to cold water;

- connection and heating of all necessary oils;

- adding a mixture of alkaline oils;

- whipping all components with a whisk;

- adding to the composition of the fat;

- pouring the mixture into molds;

- product maturation within 1 month.

The hot soap making process consists of several stages:

- the acquisition of the necessary ingredients;

- weighing all components;

- grinding solid base substance and its heating in a water bath;

- water infusion;

- the addition of alkali, which should acquire the temperature of the base;

- infusion of prepared oils;

- boiling components to a state of thick glue;

- glycerol addition;

- boiling the mixture to a transparent state.

In order to prepare a base from children's soap, you must follow the following sequence of actions:

- grinding the product with a kitchen grater;

- melting soap in a water bath without bringing it to a boil;

- heating base oils with a simultaneous infusion of water until a consistency of batter is formed;

- combining a liquid base with all ingredients, from base oil to essential oils;

- pouring the resulting mass into prepared forms;

- removing products from molds and drying them at room temperature for no more than 3 days.

Types of soap bases are shown in the video below.