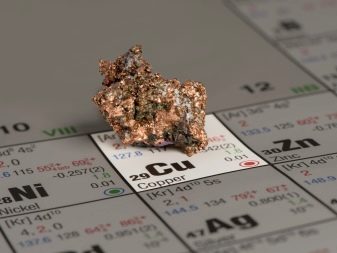

Beautiful, like gold, but many times cheaper. A type of brass that is used universally, but is not known to many. Few can guess what this is about tompake - surprising in its properties and characteristics of the metal. It is about him, about his characteristics, areas of application and methods of production that will be discussed in this article.

What it is?

Red brass - This is one of the many varieties of brass in which zinc and copper are combined in a certain proportion. Comparison of this metal with gold is based only on external similarity, because these two metals are completely different in chemical composition, characteristics and other features. Although brass has been known to mankind for a long time, but they talked about tompak for the first time only in the eighteenth century - after the discovery made by Christopher Pinchbacker. At that time, a similar alloy was actively used in England. And only after a couple of decades, its popularity spread to other countries.

On the similarity of tompak with jewelry mineral, many dishonest people could make good money by passing coins and jewelry made of brass alloy as real ones made of gold.

The metal in question can be called similor, prinzetall, chrysorin, chrysochal, oreid. Hearing these names, do not be surprised - all this is one and the same metal.

For tompak, many advantages are characteristic:

- good resistance to the formation of corrosion damage;

- excellent indicators of wear resistance;

- good weldability with other metals;

- plasticity is sufficient to apply the methods of deformation and engraving;

- the possibility of enameling and gilding;

- immunity to magnets.

Special attention deserves one of the varieties of metal, called semi-compact. Its difference from tombac lies in the percentage of zinc, which can be in the range of 10–20%. This feature explains the change in the basic properties of the metal:

- saturated yellow color;

- ductility reduction;

- increased refractoriness.

Such characteristics allow the use of a semi-compact for production of some technical details. This kind of metal is less common than tompak. This is due to the presence of a large number of disadvantages due to the high content of zinc in it.

Composition and properties

Tompak - it is an alloy in which zinc and copper are contained, and this allows us to call it a kind of brass. The composition of this compound can vary greatly:

- the percentage of copper can vary from 88 to 97%;

- the percentage of zinc should be no more than 10%.

Many properties, including strength and color, are determined by the concentration of zinc. With an increase in the content of the latter, the color changes from red to a delicate shade of yellow, which is as close to gold as possible. Also in this case, a number of metal characteristics change:

- increase in antifriction properties;

- improvement of chemical and technological features;

- lower alloy cost (compared to copper).

Tompak has a number of distinctive features:

- hardness is about 146 MPa;

- melting point is at the level of 10450 degrees;

- the coefficient of friction in the absence of lubrication is 0.44, and with the addition of lubricants, this figure decreases to 0.074;

- tensile strength in the case of tension is in the range 445–525 MPa;

- elongation after rupture - 3%;

- density - 8780 kg / m3.

The described tompak parameters can be improved by adding various components in not very large quantities. Thus, alloys with an optimal combination of key characteristics can be obtained. This metal is produced in the form of sheets or bars. Marking is applied to the metal, according to which its chemical composition can be determined. For example, the presence of the letter “L” indicates that it is brass. The numbers can determine the amount of copper.

In addition to copper and zinc, other impurities are also included, their presence and quantity can be found in specialized tables.

Fields of application

Tompak has become widespread in various fields of human activity. Here are the most popular areas.

- Production of jewelry, jewelry, interior items and kitchen utensils. Tompak is valued in this area primarily as a material that imitates gold. The noble color, suppleness and high decorativeness make it an excellent solution for such purposes.

- Tableware especially relevant in the countries of Central Asia, since such household items are valued and held in high esteem here. Brass does not tolerate contact with liquids, therefore, dishes from the raw materials in question are necessarily tinned - a technology in which a thin layer of tin is applied to a thing.

- Modern industry is also actively using tompak. Make of it wire for various purposes.

- Creature technical details carried out in various ways. The most commonly used method is based on the principle of mechanical removal of material from the surface. For processing, special turning and milling machines are used. Due to the high relevance of such a technology, many blanks from tompak began to appear.

- There are a large number of organizations whose production activities are aimed for the manufacture of rolled products. Metal in this form is processed on turning equipment.The rolling tompak is characterized by a different diameter, which can not be said about the length and basic properties, which are standardized characteristics. Such features make it easy to select the necessary workpiece for future production.

The area of use of the metal largely depends on the resistance to corrosion.

Production methods

The methods for obtaining tompak have significantly expanded since its discovery, but the essence of each of them is reduced to a single scheme.

- The composition is heated in an electric furnace to 1300-1400 degrees. With such heating, silicate is released that floats to the surface of the alloy, which allows you to remove it from there without unnecessary difficulties.

- The resulting metal is poured into a container and purged with oxygen. This stage requires the use of special equipment. This treatment provokes the release of thermal energy in large quantities and starts a chemical reaction.

- At this stage, the formation of copper occurs, which contains a lot of impurities, which reduces its properties.

- The composition is subjected to electrical cleaning using acidified copper sulfate.

- Zinc is introduced into the molten copper, which makes it possible to obtain a strong alloy with high corrosion resistance.

The process of obtaining tompak is complex, time-consuming and energy-intensive. This explains the high cost of the metal, which is still much lower than the price of gold.

How to remove an oxide layer?

Red brass not susceptible to corrosion which is its important advantage. But one of the main disadvantages is tendency to the appearance of an oxide film. The result of this reaction is the darkening of the surface of the product.

The rate of contact with water affects the rate of formation of the oxide layer. The surface with a layer of oxide does not look particularly attractive, therefore, periodically you need to remove the darkening. There are several simple and effective ways to do this.

But before using them, you need to check the product for authenticity, for this you need to use an ordinary magnet: tompak, as it has already become known, will not attract to it.

- Soap it is quite effective to return brass household items and jewelry to their former splendor and beauty. To do this, you need to make a solution of grated soap and water. You also need acetone, a cotton / cotton pad is moistened in it, after which the product is rubbed with it. Then it is washed in a mixture of soap. Such actions will restore the beauty of the noble metal.

- Via vinegar and salt You can also restore the former beauty to your favorite product. In a three-liter container, you need to dissolve 25 grams of salt and about 250 ml of vinegar, they are in every kitchen. In the resulting composition, we boil the product from the metal in question until it shines, as before. The result is not long in coming.

- Oxalic acid also helps in removing browning from products made from tompak. For this method, personal protective equipment (respirator and gloves) should be used, since oxalic acid in concentrated form is dangerous to humans. In ten liters of water, you need to dilute 170–220 ml of acid. A darkened product is lowered into the resulting solution and left there for a couple of hours.

- Lemon and salt - This is a less dangerous method, but for its implementation you will need to make some efforts and spend time. The essence of the method is as follows: dip a half of the lemon in salt and rub the darkened surface.

Products made from tombac can be made even more sparkling after cleansing. To do this, polish the surfaces with toothpaste.

In the next video you will find more information about this amazing metal.