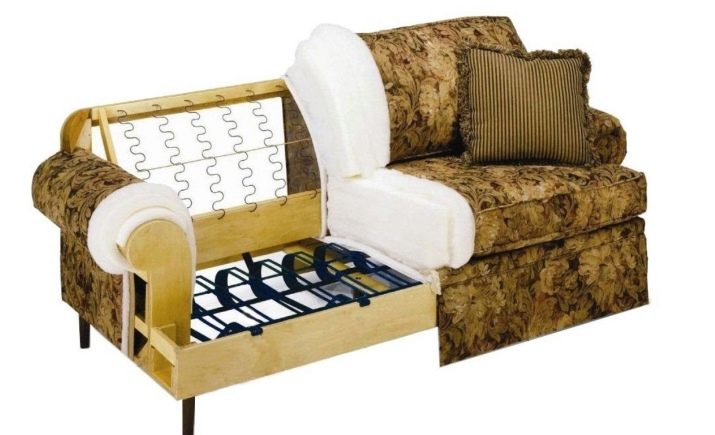

Each family has a room where all households gather on weekends or holidays. To make such meetings comfortable, it is important to have comfortable upholstered furniture. Most often, a sofa is used for such gatherings, which leads to the rapid wear of its internal content. To replace the foam in the sofa, you need to know the rules for choosing this material and its specifics.

Sofa Foam Requirements

The convenience of the sofa largely depends on the quality of the foam, therefore, in the process of restoring the filling of upholstered furniture, you must be able to make the right choice of this material. Of particular note is the furniture or sofa foam, on which the softness of the furniture and its springy qualities, as well as the operating life, will depend. To choose the right option, you should pay attention to such aspects:

- density - higher density indices will allow using furniture for a long time;

- compression stress - the standard indicator includes the value of kPa in 40% when the foam is compressed;

- material strength - it is important to take into account the values that determine the strength of foam rubber at break or elongation of the material during the gap;

- elasticity - calculated during testing by determining the indicator of the height of the rebound after compression;

- deformation - measurement of the rate of restoration of the material to its original position after deformation.

In order to be able to navigate the varieties of foam rubber available for sale, we introduced letter names:

- ST - standard option;

- HL and EL - hard foam and high rigidity material;

- HS - the softest variety that can often be found in the filling of sofas;

- HR - foam rubber with a high level of elasticity;

- Lr - soft material with a viscous structure;

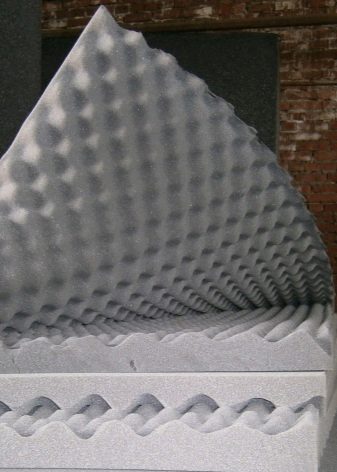

- Rtc - polyurethane foam having an increased porosity of the structure.

In addition to letter signs, there are also digital ones, where the initial figure indicates the density indicators, and the next two show the compression stress.

Varieties

In furniture production, foam rubber is often resorted to, it is difficult to imagine a stool seat and the back of a chair, sofa, top layer of a mattress for a bed without it. To choose the right furniture foam, you need to understand what varieties of this material exist and what are their features.

Standard

The standard variety is made from a basic polyol, additional components can be included in it, allowing to achieve the desired density and elasticity. This variety is often used for finishing armrests and headrests of upholstered furniture. The density of this foam is 25-30 kg per cubic meter. m

Choosing this material, you need to look for the ST marking and focus on the numerical indicators of density and compression stress.

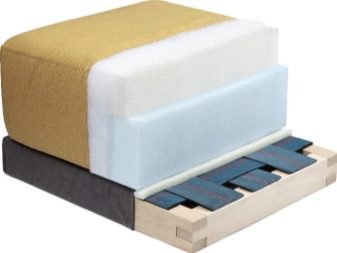

Increased rigidity

To obtain increased rigidity foam rubber, special polyols are used, which significantly increase this indicator. The density of foam rubber can vary and depends on the components that make up its composition. With a material density of 30 kg per m3, it should be used for the production of mattresses or as a sofa seat. Foam rubber, the value of which exceeds the specified value, is used for furniture that can withstand high loads. On sale you can find such products labeled EL.

Hard

Foam rubber with density indices in the range of 25-40 kg per m3 is used to fill furniture for home and office. This filler is not suitable for everyone. It is not worth using it for children's furniture, as it is too hard and hard, which will be completely inconvenient for kids. You can find out such material according to the HL marking on the package.

Soft

Foam rubber having a density in the range of 25-45 kg per m3 is used to fill a berth. Due to the good indicators of softness, firmness and elasticity, mattresses on a bed or sofa made of this material are very comfortable.

On soft foam it is comfortable to both relax and sleep, it does not leave unpleasant sensations from sitting or lying down and makes it possible to fully relax.

You can find this material by the HS marking on the package.

Highly elastic

Foam rubber having a density of more than 30 kg per m3 is able to withstand a weight of more than 100 kg, therefore it is most often used for the production of mattresses. A feature of such material is combination of initial stiffness and good load-bearing capacity. To purchase such foam, you need to look for the HR marking on the package.

Highly resilient with increased comfort

For the production of high-quality and comfortable upholstered furniture, foam rubber was created, the density of which is in the range of 30-55 kg per m3, which makes it the most soft and convenient to use. This kind of material is most often found in upholstered furniture, which is of high quality. To independently find this version of foam rubber, you need to focus on the HR * marking on the package.

How to choose?

If you need independent selection of foam rubber for filling the sofa, it is important to understand the features of this material and be able to make the right choice. Difficulties can arise with the selection of different options for the back and seat, because each option needs its own filler. Determining the look, it is best to give preference to a product with a density of at least 28 kg per m3, which will allow furniture to be used for as long as possible and enjoy the comfort of its use.

In order for the choice of foam rubber to be correct, it is worth considering the following nuances.

- The optimal sheet thickness will be 3-4 cm, thinner varieties are not suitable for filling upholstered furniture.

- It is necessary to determine the required indicators of rigidity and elasticity of foam rubber. For sitting, it is worth choosing more rigid varieties, and for armrests and a head restraint - more elastic.

- It is necessary to check the quality of the foam rubber, having studied the process of restoring the shape of the material after deformation. Inexpensive varieties do not hold their shape and for a long time return to their original position after exposure to them, which is completely unacceptable for filling upholstered furniture.

- It is important to check the composition of the material, assess the degree of harmfulness of its additives, to prevent the development of allergic reactions, which is especially important when working with children's furniture.

Not only comfort and durability of using a sofa or mattress depends on the correct choice of foam rubber for filling upholstered furniture, but also the benefits of its use.

Density

Density characteristics are considered one of the most important in the matter of selection of filling for upholstered furniture, since they are directly related to the indicators of wear resistance of the material. Depending on how dense the foam rubber will be, the values of stiffness, strength, and preservation of the original shape after deformation can change. To choose a good foam rubber, you need to pay attention not to the values indicated on the roll. The brand of the product is the most important characteristic that will help you choose the right option.

It is worth paying attention to the manufacturer - the more famous and popular it is, the more likely it is that it will be able to provide better products that can last as long as possible.

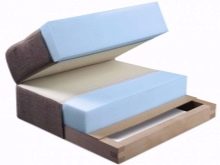

Thickness

To make it pleasant to sit and lie on the sofa, it should be as comfortable as possible. Such indicators can be achieved thanks to the correct choice of foam rubber thickness. Thick material can create good cushioning, softness and resilience, which ensures the convenience of using upholstered furniture.

The optimal indicators of the thickness of the foam sheet for a sofa are 4 cm or more.

If the sheets are thinner, then they should be used for working with armrests. If the sofa has a rigid base, it is best to use a 10 cm thick foam sheet to make the furniture most comfortable.

Elasticity

Elasticity indicators are important for the internal filling of the sofa, as they allow you to feel comfortable sitting comfortably on this furniture. To determine the elasticity of foam rubber, a simple test is carried out with a ball that falls from a height onto a foam sheet.

The higher its rebound after impact, the better the elasticity of the material. To select a high-quality version of foam rubber for a sofa, a large number of factors must be taken into account, among which are: compressive stress, permanent deformation, tensile strength, comfort factor and support coefficient. If you correctly analyze all the indicators, you can choose the most successful version of foam rubber, which will last a long time and provide the maximum level of comfort.

About how to replace foam rubber in a sofa, see further.