Any nail cutter creates a single cycle of hardware manicure. Nozzles have the necessary shapes, which depend on the type of application, and any of them cannot be replaced with another type of tool.

Hardware manicure

An alternative to circumcised manicure is hardware - it is grinding the nail plate and the skin around it using an electric device and milling cutters that perform the rotational process. This method of polishing nails does not include the use of scissors and other cutting objects.

With ordinary manicure, the cuticle is not completely evenly cut, which affects the occurrence of burrs and trauma.

Grinding nails using cutters:

- low-traumatic when properly handled with the tool, it removes keratinized areas without causing injury to the cuticle;

- allows you to form a line without flaws on the first try;

- makes it possible to grind the skin around the nail, and this is impossible to do in a trim manicure.

Varieties of tools

Hardware manicure consists of several stages. The first of them is preparatory, which consists of removing the artificial coating, drying the nail plate and cuticle. At this stage, tools for manicure made of hard alloys or ceramics are used.

A hardware manicure needs several tools.

- Fake diamond nozzlehaving a cylindrical configuration - a device that is part of all kits for beginners.The plus is that using it you can gently and layer-by-layer remove material. Disadvantages: it has lower than ceramic, the speed of removal of ordinary or gel polish.

- Cylindrical mill with diamond metal working. It has the shape of a truncated cone with a diametrical notch in the form of a spiral. The truncated part polishes the rollers from the sides, and the side - the length of the nail. Positive quality - you can gently file the nail, and negative - the notches are constantly clogged, and they must be cleaned on time.

These types of cutters include "pear". As the name implies, the nozzle in appearance resembles this fruit.

- Cutter with a truncated cone for a manicure machine. Made of hard alloys, conical, with diametrical or cruciform grooves. Of the minuses, it is unacceptable for beginners, since experience in its application is needed. It is very tough at work and removes a large layer of the nail, and if the speed is low, then the vibration is transmitted to the nail plate.

- Ceramic "corn" found its use in home and salon conditions. It has a different notch size. Pros: cuts off the varnish with high speed, while acting gently. Cons: high cost, and also there is a heating process at low speeds.

Processing of the skin around the nail occurs with the use of special nozzles.

- Nozzle needle or fissure. It is a cone narrowing and ending with a thin tip. A peculiar likeness of a pusher and scapula used in edged manicure. The nozzle is designed for one of the cycles of polishing the nail - raising the skin around it. It is placed under a certain angle, its upper part is adjacent to the extreme layer of the cuticle, and the lower part does not reach the nail. The thin tip creates a gutter between the cuticle and the nail plate, which makes it possible to prevent injury to the nail. The side of the nozzle, representing a truncated cone, lead from right to left, and the edge of the nozzle cuts off most of the cuticle. Then, with the corundum nozzle, the remaining skin is cleaned.

- Bullet head It is used for more in-depth treatment of the sinuses of the nail, this is due to the fact that it expands to the base. But for polishing the skin in the area of the nail, it is undesirable.

- Spherical nozzle applicable for cleaning the nail from cuticle residues and for grinding the side rollers.

Materials

Ceramics are used to clean the keratinized nail plate, it very quickly copes with artificial coating. Nozzles are used at low speeds. Corundum cutters are designed to gently remove the lower cuticle layer. Hard metal milling cutters are used to polish cuticles and side rollers. Sawing off gel polish with such cutters is a rather lengthy process, but they avoid injury. Diamond tools contain in their structure natural or artificial diamond chips.

How to replace?

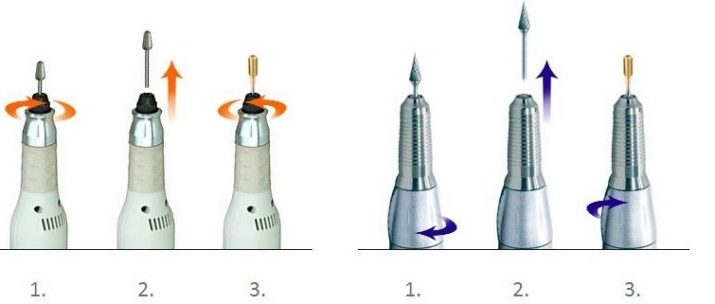

In order to change the cutter on the machine, There are several special devices.

- Hand clampwhich can be opened by pressing a button. Then open the gap for the handle and insert it.

- Semiautomatic device works at revolutions of the handle clockwise. Having replaced, you need to turn the handle in the opposite direction until a click is heard. This type of replacement is more comfortable than the previous one. It is used in appliances both in the cabin and at home.

- Auto Clamp - here you need to insert the cutter, and it will lock itself.

This mode is found in expensive appliances that are used in salons.

Beginner Tools

These include several options for simple equipment for manicure.

- A drum cylinder, one can replace other milling cutters with it due to structural features. The lateral part of it acts as a spherical nozzle, and the rib as a truncated cone.

- And also for a beginner, a nozzle that would penetrate under the side parts is desirable.

- A pointed cone is a cross between a cylindrical and fissure nozzle. The most comfortable tool to put your nails in order.

- Nozzle for polishing the nail and the skin around it.

- Ceramic milling cutter with small teeth that will allow you to remove the usual coating and gel polish without straining.

Specialist toolkit

Such equipment includes several milling cutters.

- Spherical mill with a diamond dusting. It is difficult for beginners to work with her, because in the absence of skills, a nail can be injured.

- Small size cutterstreat rough skin near the nail. A fairly large ball is used to polish the skin around the nail. The specialist selects a tool depending on the structure of the client’s nails.

- Ceramic milling cutter - "corn", in the absence of skills, it heats up very much, starts to vibrate and can damage the nail. Therefore, for beginners, it is better not to use such a nozzle.

Characteristics

German ceramic milling cutters are endowed with varying degrees of abrasiveness, which is the ability of the nozzle to remove the substances with which it is in contact. This property arises due to particles whose caliber depends on where they will be applied: nails, cuticle or varnish. The degree of abrasion is determined by the color of the rim of the milling cutters with diamond spraying and ceramic.

- Black coloring is characteristic for very rough products. On the coarsest two rims. Such products are used to remove extended nails, they should not have contact with the skin. They are used only by experienced professionals.

- The green rim indicates the spraying of hard crumbs. Such tools are used to cut varnish and keratinized skin on hands and feet.

- Cutters and rollers are processed with cutters with a blue rim, this is the most widely used level of abrasiveness.

- The red rim is small particles, such products are suitable for filing a nail and cuticle.

- Yellow - the smallest particles, cutters with their presence have the smallest abrasiveness.

- White rim - cutters used to polish the nail.

Security measures

The use of hardware manicure at home should be carried out in accordance with the recommendations. It is necessary to use disinfectants so that the instruments and the area of their use are disinfected. With caution, you need to use devices with a strong speed of rotation, which will help prevent injury.

Grinding the skin around the nail should be done from left to right. In this case, the cutter is held parallel to the nail. When polishing the sinuses of the nail, do not touch the nail.

Stages of the procedure

Hardware manicure includes a number of steps.

- Using a cylindrical cutter, lift the skin around the nail and remove its excess, moving the tool in one direction. The main thing is not to press on the nozzle in order to prevent injuries.

- Using a fissure cutter, treat the raised skin and sinuses, which will give the skin smoothness and eliminate peeling.

- Corundum cutter is used to prepare the skin around the nail for cleaning and eliminating cracks.

- Using a milling bullet, they process all inaccessible places in the sinuses of the nail. This nozzle is not suitable for processing cuticles, as it will cause cuts.

- The use of a spherical mill cuts the cuticle to the end. Pressing movements first, then polishing.

- Now the stage of polishing nails and the formation of the desired type.

Instrument sterilization

Tools for manicure nails should not be dirty, they should not have germs. They must be sterilized with the use of various disinfectant solutions, such as Alaminol, Optimax, Gigasept, Korzoleks. These formulations are sold as concentrates and must be prepared for the upcoming disinfection.

During the disinfection procedure, the stiffness of the material and the depth of the nozzle notches must be taken into account. If the coating is soft, then it can deteriorate from prolonged disinfection, so the procedure time should be reduced. Sterilization lasts from half an hour to 40 minutes on average.

After disinfecting the compositions, the cutters go on to the further stages of sterilization: cleaning under running water, manual cleaning using a brush, ultrasonic cleaning, and placement in an autoclave.

Care

In order for the equipment to serve for quite a long time, they need to be looked after.

- When doing a manicure, you can not put too much pressure on the nozzle. This can cause the head to warp at the base of the handle, making the tool unusable.

- Changing the nozzles must be carried out in accordance with special rules, usually they are indicated in the manual for use of the device.

- After passing the disinfection, the instrument is stored in a case where it will be preserved from moisture, dust and various external influences.

Reviews

Reviews of hardware manicure are mostly flattering. Here, as a positive point, speed and a comfortable state during its implementation are noted. The main positive feature is that such a manicure is durable. A new treatment can be carried out in two or three weeks.

Negative reviews are caused by going to a master who has low qualifications, in this case the result is not at all pleasing. In order to perform a manicure well and with high quality, high-quality cutters are necessary.

About what you need to know about nail cutters, see the next video.