Once upon a time, there was nothing to replace the traditional and only (there were practically no options) wooden cutting board. Relatively recently, plastic and glass products appeared in kitchens, which quickly pleased the housewives. But not everyone. Someone basically refuses plastic, someone does not like to work with "noisy" glass. However, thin wooden cutting boards quickly lose their working appearance, require deeper washing, and even from the point of view of aesthetics raise numerous questions. But there is a way - end cutting boards.

Features

They learned their peak of popularity quite recently: with the advent of Instagram, mistresses of the whole world began to understand without magazine trends that today is in fashion, which is really stylish, cozy and comfortable. In many kitchens of the owners of Western accounts appeared “thick”, solid-looking chopping boards. The familiar kitchen picture was changing, and the demand for Scandi-style household items (and the like) grew very high. They began to pay attention to impressive products in stores, and enterprising craftsmen and private firms responded to an urgent request.

But they came up with endboards a very long time, when not just Instagram, but even electricity was not there. The first end board was an ordinary wood cut with a rather rough finish, but still quite comfortable.

A high-quality end board can even weigh several kilograms, and its price is much higher than a penny “thin piece of wood”. But these are not just rough saw boards: a modern end board is a manual, rather heavy and painstaking work.

We need special wood, safe, non-toxic glue, special grinding of each bar, and fit. And also processing with special oil in a number of layers. Even the most hardworking craftsman will not make one product per day: the work takes 4-5 days, if you include drying here. But the result is not just a kitchen accessory, but a faithful, durable, durable assistant in the most important culinary manipulations.

Advantages and disadvantages

The benefits are definitely greater. And if they cause you doubts, probably theoretical knowledge can not be compared with practice: it is enough to spend one day in the kitchen with the end board, as you simply do not want to return to other options for cutting.

Here is a description of the 8 undeniable advantages of the end board.

- The structure of the board is such that the end boards retain their original appearance (very aesthetic and solid) for as long as possible. Their durability is beyond praise. And this provides a special gluing of wood fibers, due to which they are parallel to the movements of the knife. The knife does not cut them, but simply opens it, to put it simply. And after cutting, most of the fibers close back. That is why the cuts on the product will not be visible for a very long time, several years.

- The most durable grades of wood are taken; when they fall, they will not crack. On a thin board with a shredder, the risk that thin chips will fly is very high. With the end board, this is out of the question: the safety of your culinary experiences remains valid.

- When the master finishes making the board, he must cover it with mineral oil. And the owner himself during the operation must do the same. These are not just obsessive aesthetic requirements: mineral oil helps the faceplate remain water-repellent.

- Endboards are antimicrobial in design. As already mentioned, the fibers of the tree are moved apart, not cut. And they very quickly close back, so the bacteria have no chance to get inside. But thin wooden boards are often blamed for this.

- The functionality of their boards do not lose for a very long time. Cutting meat, fish, minced meat, noodles, vegetables - any manipulations can be performed on a cutting board of this kind.

- An end board can also be used for serving dishes - this is facilitated by its attractive appearance. Even if you were taken aback by spontaneous guests, cut sausage (meat, ham), vegetables, herbs and cheese, and serve it all right on the board. You can put a small saucepan there. Be sure that guests will like it, they will consider you a modern and creative person - in addition, for such an organization of dinner you do not need a lot of time and unnecessary panic.

- No complicated board care. Together with it, you should buy a bottle of mineral oil (or linseed oil), and wipe the board with it after use. Previously, the tree should be washed and dried.

- Ease of use. The manufacturer mainly makes models on legs that are equipped with a non-slip coating. The board does not slip, the owner is protected from injuries.

It remains only to list the cons - there are two of them.

- Price - it is significantly higher than that of thin boards. But the end option will last much longer, and from the point of view of the sanitary condition it is many times more reliable.

- Weight - the board is heavy, no doubt, but this is hardly such a drawback. She will fall less often, will not slip out of her hands.

Dimensions and shape

The shape of the cutting board can be different: square, round, oval, ellipsoidal. Which one to choose is a matter of convenience for the owner. For some, the square version is more practical, someone accepts only the round - there can be no objective advice.

As for the dimensions, here you can evaluate the length, width and height. The length can be from 10 to 70 cm, the width is from 10 to 45 cm, and the height is from 3 to 8 cm. More often buy boards 30x40 cm with a thickness of 3 cm.

The type of grip on the end plate is also important.Slots for the grip can go along the sides from below, there can be one hole in it from the edge, one in the corner, or even a board without slots and holes.

Tree species

The wood used for the manufacture of end products is a list of at least 10 items. Each type of material has its pros and cons, important manufacturing differences.

Let's consider the main options.

- From the pine. Cheap building material, in short. Soft wood, inexpensive and affordable material, easy to process. But specifically for the board, the option is far from the best.

- From the birch. The breed is medium hard, good in processing, but the birch accessory will turn black pretty quickly, and it is also afraid of dampness.

- From beech. Strong and solid wood, but the tree is characterized by strong hygroscopicity, it absorbs moisture, therefore, such products are always varnished.

- From oak. Good material with high density. And although it is almost an ideal option for a cutting board, only one thing can confuse - the cost. Oak is not easy to process, because of such costs.

But they still make products from larch, from mountain ash, from bird cherry - but they are definitely inferior to oak. But almost all the boards presented are still superior to thin chopping wooden ones. And this is due to a different arrangement of fibers: on the end model, they are perpendicular to the surface for cutting, and not parallel.

Attention: if you choose this option, the knives will stay sharp longer, sharpening will be a rare event. For the layman, this circumstance may not be so important, but for professionals it greatly facilitates the work.

How to choose?

When choosing a kitchen accessory, pay attention to weaving options. The board consists of pieces, so masters can make a different picture.

Consider the varieties that are more common than others.

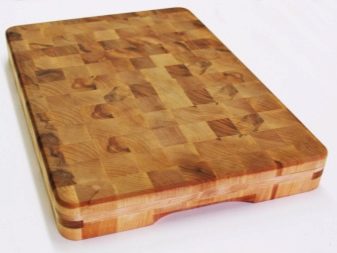

- Chess weaving. Two-color sticks are glued by the master in a checkerboard pattern. If you wish, you can actually play chess on such a board, although it is much more convenient to use it for cutting.

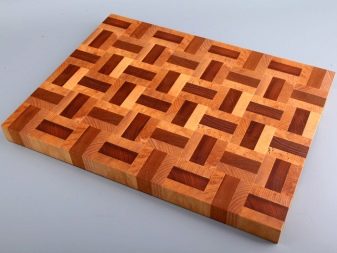

- Basket weaving. The wood bars are intertwined, although this is only an appearance, the pattern is similar to a wicker basket.

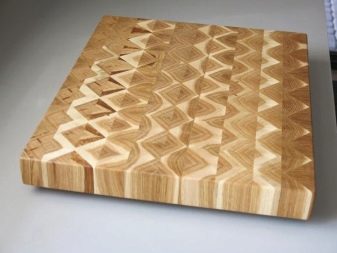

- Complex ornament. The master can make a complex ornament on the surface on an individual request, he can even cut out the whole picture. But the price for such a board will increase, copyright works are always more expensive (especially if you need a 3D effect or some other).

And also you can become the owner of a board with a container. It will be a very thick board, inside of which a container “hides” where the cut material enters. As a rule, the container is made of stainless steel. In another way, such models are called end-boards with gastronomic capacity. Of course, this is convenient, but it’s still more common for someone to work on a classic board made of quality material. Therefore, there can be no objective comparison.

How to care?

Any kitchen utensils will last longer if you arrange proper care for it.

The principles are not the most complex.

- Do not leave the product wet. No need to pre-soak it before washing.

- After use, wash the board in warm water using standard detergents. Soap, vinegar and soda can also be used for washing, if they are more familiar to you than household chemicals. After washing, you need to remove moisture with a towel, dry the board.

- In the dishwasher you can not wash such an item (this is always indicated in the instructions).

- In the role of the stand, you can use the end board, as well as serve dishes on it, but only non-hot ones. A typical mistake is to use the board as a stand for the pan, so you will quickly render it unusable.

- The board must not be placed in the microwave or oven.

Do not store the board next to the stove, battery, any heat source. This deforms it, negatively affects the quality of wood fibers. And do not wash it with hot water!

The main thing is to properly process the board with mineral oil. In the warm season, it is enough to do this once a half to two months. When radiators work in the house, you have to speed up the procedure. On a perfectly washed and dried board, you should apply a whole tablespoon of mineral oil: no longer needed, your task is to impregnate the material, and not redeem it in oil.

Rub the oil in a circle using a cotton swab. It is important to cover the entire surface with oil: if you miss some places, the treatment will be of poor quality.

Process the item “out of turn” if you notice that the liquid does not linger on the surface of the board, but is absorbed into it, if the product has noticeably brightened, if it has become rough to the touch, knife cuts became visible.

Suitable for processing:

- mineral oil (buy in carpentry and cosmetic stores);

- liquid paraffin (in pharmacies);

- icon oil (in church shops).

Other impregnations are absolutely unnecessary, it is completely unnecessary to cover the object with varnish or something else. Moreover, you can damage the product and it will no longer be edible.

Proper maintenance guarantees long years of product service. And it will delight you with its durability, ease of use and impeccable aesthetic appearance. The acquisition is definitely worth the money.

See the following video for the manufacture of an end cutting board.