A meat grinder is a very necessary device in the kitchen. For grinding products, there are other devices today, but the meat grinder is a more traditional option, besides it has simple functionality. The cutting knife is almost the main element of the meat grinder. Unfortunately, in low-quality models, this is also the most fragile detail.

Features

The meat grinder knife is characterized by various modifications. A popular variety is with four cutting blades. Three- and two-blade cutting parts are also available, but are less common. Knives for an old manual meat grinder differ in their workmanship. For example, now this item is made of soft stainless steel. Knives used to be made of high-carbon strong tool steel.

The main differences between domestic and foreign knives are in the appearance of the cutting tip. The cutting edge of the classic knife is in front when viewed from the vertical. The cutting process is provided by the slip, but it is small. Such a knife is not very effective in work.

Modern electric meat grinder knives are usually saber-shaped. Thanks to the strongly shifted cutting edge, good sliding is ensured. The efficiency of saber-shaped knives is high. They are widely used for household electric meat grinders.

Particularly high performance are meat grinders, which are used in catering establishments. Knives on such units are significantly different from those used in home meat grinders. The profiles of the cutting edges are straight, and the blades themselves with protrusions.

Such profiles provide the same sliding force. The conditions for cutting the product with such a knife provide good efficiency.At the same time, in contrast to the saber-shaped knife, which acts as a spatula, spreading the chopped meat in front of the grill, the knives for the professional meat grinder chop the product, and in 10-15 minutes.

A knife with saber-shaped tips has recently been less commonly used in household meat grinders, as it has a major drawback - it pushes meat to the edges of the auger. The housing in front of the grill is "overgrown" with the product, productivity decreases, the device needs periodic cleaning. When you need to process a limited amount of meat, it is invisible. The process becomes difficult with bulk processed batches.

It is important to pay attention to the features of the knives at the unit, especially if it is planned to process a large amount of meat or other products at home. The optimal power of a home electric unit is considered to be 250-700 watts, which allows you to make minced meat from 2-3.5 kg of meat in 1 minute. If the family decided to harvest a sufficiently large amount of minced meat, you can take a closer look at models from 800 watts - they usually have increased functionality.

Complete sets of meat grinders are different, but the wider the functionality, the higher the price of the device. If many nozzles are not needed to use, it is better to choose a simple model, but with a high-quality cutting element.

Types and forms

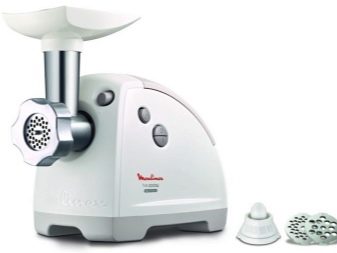

These parameters are closely related to the type of meat grinder. Among the manufacturers of meat grinders are popular Bosch, Moulinex, Philips, Zelmer, Kenwood, Redmond, Polaris. Manual and electric models do not have other fundamental differences, except that the latter are characterized by greater power. They can successfully process even veined frozen meat. In addition, with the help of the device you can get not only the classic stuffing, but also an option chopped into small pieces.

The largest number of positive reviews is collected by the German manufacturer Bosch. Models, although not the most powerful, are distinguished by high-quality assembly and durable components. Zelmer is the second most popular manufacturer, supplying quality equipment with low-cost components. The more popular this or that type of equipment, the easier it is to select component parts in the future. They are often interchangeable, at the price of inexpensive.

For example, the listed types of meat grinders work in an identical way, the main components are made of the same material - stainless steel, the body of the electric appliance is plastic, there is a necessary minimum of additional nozzles that are used to make sausages and other delicacies. Despite the simplicity of the device, there are many manufacturers today, so there are a large number of types and forms of accessories.

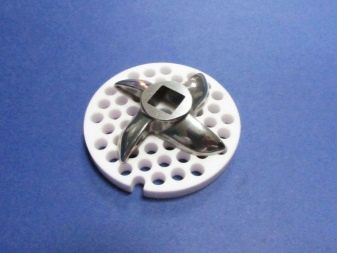

In addition to the blades in the knives, the base configuration is different. The most common elements are:

- hexagon;

- square.

Due to the difference in the forms of the base, the element can be difficult to choose for a specific model of a meat grinder. In addition, some manufacturers produce different types of knives for various series of meat grinders. So, a popular brand Moulinex meets the base "hexagon" and "square". Zelmer offers accessories only with a square footprint. Bosch, Braun, Kenwood, Gorenje also made with a square base.

The blade shapes of the varieties are different, but this only plays a role in processing efficiency. A problem can only arise if large quantities of meat are processed. Blades are single-sided and double-sided. The operation of the latest models is simpler, since you can insert them on either side. With the first type of difficulty arise in inexperienced housewives. In this embodiment, the flat side of the knife must necessarily touch the grill, which is installed behind the disk. The convex side should be on the auger.

Over time, the meat grinder knives are dull. Elements lack a self-sharpening function, but the steel of ordinary cutting elements can be sharpened at home.A meat grinder can be sharpened with sandpaper, the main thing is to timely consider the problem.

Self-sharpening knife included Moulinex ME 6201, Kenwood MG-700, Bosch MFW 68660. The price of devices is from 6500 to 18000 rubles.

In a separate variety of cutting elements, you can include two-blade cutting knives, which are included in the set of professional meat grinders of the old model. The item is set to MIM-300, MIM-300M, M-250 (UKM), TM-32, TM-32M and others, with a diameter of the used details of 82 mm. Such an element has holes, and at the entrance they are narrower than at the exit. This is necessary so that the processed product comes out more easily.

If you put the wide side from the entrance, and the narrow one towards the exit, then there will be some kind of prepressing of the product. In enterprises, such a knife is used for processing dough products, for example, pasta.

Selection rules

The quality of the cutting knife affects the performance of the meat grinder, so it is important to choose the right metal accessory. Steel is the most common material for making knives, but elements from cast iron have been found recently. They differ in longer operational term.

Product processing efficiency will increase from more cutting edges. Four-bladed constructions with a landing hole in the center are most widespread - it should securely fix the knife on the screw element.

Meat choppers can be forged or stamped. The first version of the products is characterized by increased weight, but improved strength. The cost of such cutting elements is usually high. The stamping will be lighter in weight, but with less strength. In the price stamped knives are cheaper.

The assortment of meat grinders found in the country's stores is quite large. Chopping knives are also diverse in specifications, but some models are considered interchangeable.

For example, if you need a cutting element for a Moulinex meat grinder, take a look at the details from Tefal. The HV3, HV4, HV6 series are suitable for the ME7001, ME7011, ME7108 and Crups HV6, GVM2 series. The knives of these instruments made of stainless steel have the same dimensions - 4.5 cm, relatively inexpensive.

The knife from the Zumman unit with a square seat is compatible with many models, for example, Daewoo, Verloni, Scarlett, Panasonic. The product has excellent strength characteristics, easy to install, inexpensive.

Bosch offers customers a set of knives along with a meat grinder, but if they are worthless, you can use parts from Zelmer or Philips. The strength quality of the products is high, the price is small.

Good compatibility with knives from the meat grinder Braun, Philips. The cutting parts of these devices have a long service life, but if they become dull, you will have to spend a significant amount from the family budget, since the elements are expensive for the price.

Redmond - a Chinese meat grinder is characterized by the characteristics of a cutting knifewhich is difficult to find among interchangeable elements. The knife is larger than all others - 5.4 cm, thickness - 8 mm, with a fairly wide seat. The quality of the knife is good, but it has the main disadvantage - the high price and the absence of interchangeable elements.

Scarlett is a widespread brand, and therefore the elements for these meat grinders are quite expensive. Kitchen has the only option for a suitable knife. The product is practically no different from the standard element, has a long service life, good durability.

Domestic meat grinders of different brands - "Rotor", "Miracle", "Diva", "Extra", "Power" equipped with an identical cutting part, therefore, are considered interchangeable. Products are characterized by good strength, durability, the price of a cutting element is low.

Subtleties of operation

The following recommendations come in handy for the long life of the chopper.

- For processing, it is better to use meat cleared of tendons.

- To protect the metal, it is best to rinse the product immediately after use with running water.Do not soak the knife in liquid solutions. After washing, the cutting part should be dried immediately.

- Do not overload the meat grinder in large pieces. An element may simply not be able to cope with a lot of meat.

- Even the best knife dulls over time. For sharpening it is better to give it to knowledgeable people. A stand-alone approach requires practice and related additional elements. At home, it is possible to sharpen knives that have not yet become very dull.

Sharpening at home

To do this, you need fine sandpaper, which should be laid out on a table. The cutting element must be driven along the surface of the sandpaper in a circular motion. The knife itself can also be processed, but it is better to take the sandpaper even smaller.

After processing, it is recommended to rinse the product with warm water using detergents. The remains of grains from paper should be completely removed. The sharpened knife should be dried, and only then used in the work.

For sharpening, you can use the usual "whetstone". With this method, the abrasive element must be placed under running water, take a knife and start the clockwise rotation, directly under the running water. In this case, the pressure on the sharpener should be uniform. The sharpened part will have a smooth and shiny surface.

The chopper should be evenly pressed to the grid from the meat grinder. You can verify this by attaching the details to each other. By the way, many users also recommend grinding the grate itself periodically - this will increase the efficiency of the meat grinder. Remember that both parts must not be washed in a dishwasher.

See how to sharpen a meat grinder knife in the video below.