Sinks made of natural stone have already ceased to be an exotic phenomenon in Russia. Natural rocks and minerals, composite materials, including quartz agglomerate, used for the manufacture of kitchen sinks, have a lot of advantages. Stone sinks for the kitchen managed to gain popularity with connoisseurs of modern design. Such plumbing fixtures look much more respectable than classical metal options, stronger than ceramics and go well with the most relevant interior solutions.

Advantages and disadvantages

Artificial and natural stone kitchen sinks today are produced by many well-known brands in Russia, Europe, and the USA. Stone kitchen sinks are widely used by individual homeowners thanks to the obvious advantages this shell option has.

- Superior durability. The stone surface is not afraid of mechanical damage, shock loads. They easily withstand contact with sharp metal objects. And falling heavy dishes will not cause material deformation.

- Heat resistance. Natural stone withstands all temperatures. Artificial materials have some limitations, but they quite successfully cope with the task of washing dishes and vegetables. Just follow the manufacturer's recommendations.

- Hygienic safety. Both natural stone and its artificial counterparts make it easy to maintain maximum purity.The coating is not porous, eliminates the accumulation of bacterial plaque, the appearance of rust or an unpleasant odor.

- High chemical resistance. Stone sinks do not react with acids and alkalis, maintain the integrity of the coating after contact with other aggressive substances.

- Easy to care. Stone sinks are easily cleaned of impurities, do not require complicated maintenance, and if necessary can be restored.

- Long service life. The product will not need a replacement even a decade later, it will retain an attractive appearance after many years of use.

- Wide model and size range. You can choose built-in, overhead, hanging options, give preference to round, oval, square or rectangular sinks. The color scheme and even the texture of the material is also much more diverse than that of metal structures.

- The minimum noise level. When in contact with a stream of water, the surface of the stone sink does not make unnecessary sounds, moreover, the liquid flows smoothly, and does not spray on the sides.

Not without flaws.

- Stone kitchen sinks have a fairly high cost, they can hardly be called a budget option.

- Such products are much more massive, require a solid foundation. They must also be transported and installed, taking into account the severity of the selected shell.

- With a strong impact, even a stone can get chips and cracks.

Varieties of shells

The variety of stone sinks can be envied by any other plumbing options. Products designed for premium kitchens are developed by designers and harmoniously fit into the design of the most spectacular interiors. On sale are presented single and double sinks, recessed bowl versions, dish drier.

There are models with different installation methods, and all these points have to be considered when replacing an old sink with a new one made of natural or artificial stone.

Forms

Among the options for the forms of stone kitchen sinks, some are considered the most popular.

- Round. A popular design solution that takes up little space and is well suited for different installation methods. Deep round stone sinks to avoid splashing water, suitable even for small kitchens.

- Oval. They look spectacular, increase the useful area of the interior of the sink, and look good in island structures.

- Rectangular or square. The most common option, it fits well in straight countertops. A single sink is most often rectangular, a double one combines 2 small square sinks.

- With a wing. This is the name of a platform with a ribbed surface located to the right or left of the bowl, designed to drain water. Such sinks are convenient if they are often rinsed with fruits, vegetables, individual cutlery.

- Corner A rounded or trapezoidal stone sink is easy to place in an L-shaped or U-shaped kitchen.

- Arbitrary. They are made to order according to individual sizes and parameters. It is possible to create products with one straight edge and semi-oval, complex double options, in the form of combined circles.

When choosing a mold for a stone kitchen sink, it is important to consider all factors: from the size of the countertop to the location of the sink.

Dimensions

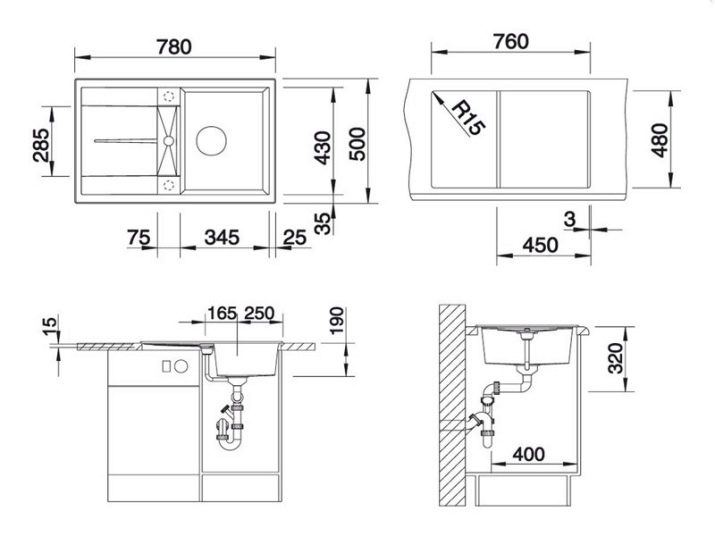

The standard dimensions of a stone kitchen sink are determined taking into account the size features of the kitchen set. A small sink will have a width of 45-50 cm. The standard version is 60 cm. Large sinks reach 80 cm in width. The length parameters are individual: from 50 to 100 cm. The features and characteristics of the product affect it.

The weight of the stone sink depends on what material was used. Products made of artificial raw materials usually have a weight in the range from 8 to 18 kg. Natural materials are even heavier, require a massive or reinforced base.

For example, a product from granite or basalt rock with a standard washing width of 60 cm can weigh up to 80 kg.

Installation methods

All used stone sinks for the kitchen are divided by the method of installation.

- Recessed. Most popular today. The sink is built into the countertop, occupying a place in the general design of the headset, and shelves and drawers of the storage system are located nearby. The bowl is located below the level of the countertop to form a protective board to prevent overflow of water. As a rule, such sinks are the most capacious, they are often supplied with a wing.

- Mortise. They are fixed under the countertop, then the seams are sealed, and the design is used for its intended purpose. Not the most convenient option, requiring a large amount of work. That is why it is almost never used by professional installers.

- Overhead. A fashionable idea that allows you to choose any shape of the sink, vary the depth of the bowl. Thanks to the bumps protruding above the countertop, you can not worry about splashing water. But the design features do not allow to make such a roomy sink.

Materials used

Among the materials used in the manufacture of stone sinks, natural stone and its artificial varieties are distinguished. Depending on the performance, you can select composite and solid cast optionsproviding opportunities for reliable imitation of natural raw materials. Natural stone can be polished or polished, maintain its texture, acquire mirror smoothness.

A natural stone

Among the natural minerals and rocks used to make sinks for the kitchen, granite and basalt are the leaders. By their hardness, they are at the top of the Mohs scale, have high impact resistance and chemical resistance. Contact with acids, mechanical stress and other external factors in no way affect their performance.

It is not surprising that sinks for kitchens made of granite and basalt often have an unlimited manufacturer's warranty.

Marble and Travertine — one of the most beautiful types of natural stone. They are distinguished by the uniqueness of the ornament, heat resistance, resistance to moisture, UV rays. They are ideal for constant contact with water, they allow you to realize almost any design fantasies and solutions due to good ductility.

When using marble and travertine sinks in the kitchen, it is very important to remember about a number of restrictions characteristic of these materials. Contact with vinegar, lemon juice and other acids will have to be excluded: they destroy the structure of the mineral. Due to the porous surface, there is a risk of staining light marble with bright vegetables and fruits, other products.

With intensive exposure to the surface with sharp cutting objects, scratches can be left on the stone.

Onyx kitchen sinks are an exclusive design solution. They are quite expensive: the stone is semi-precious; it is not mined in large quantities. The translucent structure of the material allows the use of backlighting, creating unique in its beauty solutions. Onyx is resistant to moisture, lends itself well to processing, from it you can create complex curly products.

Artificial

Sinks made of artificial stone are of high quality. Visually, they are almost identical to natural ones, but they are much cheaper. The composition of the material usually distinguishes composite substances (their share reaches 20%) and stone chips, which acts as the basis. In some cases, coloring pigments are additionally used to give the design the desired color.

- Acrylic. In this case, the sink is created in the form of a molded product from various components: acrylic resins, polymerizing substances, mineral inclusions. Acrylic stone sinks are the most affordable, but in operational properties they are much inferior to natural and other artificial counterparts.Hot dishes cannot be placed in such a sink, and the surface is easily scratched.

- Artificial granite. The most durable version of sinks made of artificial stone. Granite chips retain their strength even in crushed form, the composite material acquires additional plasticity, and allows for the creation of products of the desired shape, regardless of their features and complexity. The higher the content of natural stone in the composition of the product, the stronger it will be. To improve performance, quartz may be mixed into the composition.

- Artificial marble. It is created on the basis of marble chips by casting. This material also has certain disadvantages. Often, unscrupulous manufacturers create such sinks based on polyester resins, making them cheaper and making products less resistant to external factors. Sinks made of cast marble do not tolerate temperature extremes, mechanical abrasion. Over time, the material fades, the protective layer is erased, the surface becomes porous.

- Porcelain tile. This imitation of stone is composed mainly of clay and quartz sand. The similarity with the rock is only superficial. The material is quite durable and practical, not afraid of chemical and thermal effects, can withstand acidic, alkaline effects. But porcelain stoneware is not very resistant to shock loads, the sink may crack, crack.

Color and surface type

Sinks made of artificial stone can be made in almost any color and shade. The most popular are gray and graphite, white, black options. Beige sinks are embedded in brown and cream worktops. In addition, for designer kitchens, manufacturers offer bright pink, blue, green, red, chocolate color options.

For individual production, the manufacturer can use pigments at the request of the customer.

In a monophonic version, artificial sinks imitating stone are rare. Most often, their surface is covered with an ornament that recreates the texture of the mineral. Such a pattern looks more interesting, hides small chips and defects, traces of pollution are not so noticeable on such a surface. Among the popular options for drawing - black specks on a white background or light on a dark, gray or anthracite.

The surface texture of the artificial stone used in the manufacture of sinks is more diverse than its natural counterparts. It can be a glossy or silky matte finish, imitation of an antique mineral or shagreen, when the sink looks like it has been cut down from a single block of stone. The more structured the surface, the more reliable the simulation will be. The color scheme of sinks made of natural stone is no less diverse. It all depends on the choice of rock material.

- Granite It is pink, gray, red, black, beige. There are even rare blue, yellow, green varieties. Depending on the field, grain size, color intensity change.

- Marble valued above all in white. Black stone with white streaks, red and pink mineral looks pretty pretty. Beige, yellow, gray and green marble look noble.

- Onyx has not so rich color scale. Most often, the background color is white or beige, greenish, pink, orange-red. Due to the striped layered structure, its tone is never uniform.

- Travertine It has a characteristic white color with a yellowish tint of ivory. In addition to white and beige flowers of sinks, you can find yellow, gray and red options.

- Basalt always has only black or graphite gray colors.

The surface texture of natural stone provides only 2 processing methods: polishing to mirror smoothness and creating a rough structure, like natural tuff. Such options are available for granite, marble, travertine.

Manufacturers rating

The rating of stone sink manufacturers includes both European and Russian brands. Natural stone products are presented on the Russian market mainly in the domestic version. Among the leaders are companies such as "Plumbing G", Sheerdecor, "Paradise", "OrganStroy".

Most brands have a choice of ready-made models according to the catalog, the opportunity to create products for individual orders.

One of the leaders among foreign companies is a Japanese manufacturer Omoikiri, self-extracting stone using a special technology. The rating of manufacturers of sinks made of composite or acrylic includes several brands.

- Blanco. A German company using Silgranit material, 80% granite chips. In the catalogs of the company there are sinks with various designs that are not afraid of mechanical, thermal influences, sunlight.

- Franke Another German brand that manufactures sinks from the patented Fragranite material. The catalog contains products in 9 colors, many options for shapes. Composed of 20% acrylic and 80% granite.

- Longran. A company that has been supplying the Russian market for more than 20 years. Production is carried out in Italy, India, Turkey. The basis of the products is composite material Lonstone.

- Teka. The German brand that manufactures products from Tegranit Plus material containing from 70% of the natural filler - stone chips. The rest of the volume is filled with a binder of acrylic, coloring pigments. The catalog presents a selection of 8 colors, there are products of different shapes and sizes.

- Granfest. A Russian company that has been producing competitive products for over 15 years. The brand has its own design bureau, modern production lines.

- "Polygran-M". A company from the Russian Federation that produces stone sinks under the Tolero and Polygran brands. The price of products compares favorably with the offers of European competitors.

These companies list of manufacturers of sinks made of artificial stone is not limited. When choosing a brand, it’s important to pay attention to how high quality raw materials does he use. There are quite a lot of fakes on the market that do not meet security requirements.

How to choose?

The choice of a stone kitchen sink largely depends on the interior design of the room. There are many attractive and interesting design options for sinks, their shapes, colors. But there are criteria that largely determine the service life and other characteristics of the material. You must pay attention to individual parameters.

- Material type. Natural stone is too heavy for installation on budget headsets made of wood-based panels. Artificial options often look no worse, but noticeably lighter than their counterparts. Quartz and granite composites are stronger, more durable than marble and acrylic.

- Size and shape. Large, roomy sinks for the kitchen are highly appreciated. But you need to consider the parameters of the countertop. In a standard headset in an apartment, it is better to put a sink no wider than 60 cm, square or corner. In the kitchen with the island, you can use a sink of any size. Oval and round models are mainly built into designer kitchens.

- Sink design. For a large family or a hostess keen on cooking, a double sink or a model with a drying wing will be useful. In a bachelor apartment, a compact square or round sink without high sides will be appropriate.

- Color and design. The classic white stone sinks look dull. It is much better to decorate the interior with a black, gray, beige sink or choose more original options. It’s worth focusing on the general style in the design of the room, the personal preferences of the owners.

- Budget. Prices for sinks made of natural stone start at 20 thousand rubles for one product and can reach 200-500 thousand rubles in a designer design. Artificial analogues are much cheaper. Russian products cost from 3 to 8 thousand.rubles, foreign - up to 1,500 dollars.

Operation and maintenance

To extend the life of sinks made of natural stone, they must be periodically covered with special protective impregnations. Such materials increase moisture resistance, prevent the absorption of odors and pollution by porous minerals. In the case of marble and travertine the presence of impregnation will reduce the risks of discoloration of the surface.

Coverage is updated regularly, at least 1 time per year. Granite and basalt are processed every 5 years.

Cleaning the surface of natural stone sinks is recommended using mild detergents and cleaners. The use of metal sponges and brushes should be excluded. The best choice would be to use a soft cloth and a neutral detergent with a degreasing effect.

Caring for artificial stone products also has its own characteristics. Necessary:

- comply with the installation rules, carefully seal all joints;

- after each use, clean the walls and bottom of the bowl, if possible remove moisture from them;

- weekly perform cleaning with special detergents;

- when placing hot dishes, use stands;

- protect budget models of sinks from direct contact with boiling water.

Careful attitude to stone sinks allows to extend the service life of these products even if they are operated in difficult conditions of a modern kitchen. It is worth observing all the recommendations and making sure that the surface of the bowl after use remains clean.

On how to choose a stone sink for the kitchen, see further.