Diamond is a natural mineral, which is carbon with an allotropic crystal lattice. Due to its molecular structure, it is an extremely hard material that can be stored indefinitely.

The chemical composition of diamond can be changed under the influence of various factors: high temperature, pressure and / or vacuum. As a result of their action, the diamond turns into another chemical element - graphite, which has a different composition of qualitative characteristics.

Diamonds are obtained by natural production and by artificial production. In the second method, the chemical element graphite is subjected to high temperature and pressure. Graphite material changes its molecular structure and turns into rough diamonds, acquiring the characteristic properties of strength.

Before further use, the resulting raw material needs additional processing. The factor of increased diamond hardness requires a special approach to the methods of its implementation.

History

The history of diamond mining is extremely young. This is due to the complexity of the search and extraction of the mineral, as well as the difficulties associated with its processing. The processing technology of the described material with the help of another diamond began to gain popularity only by the XIV-XV century of our era. Until this time, this method was used only by ancient Indian masters who carefully kept the secrets of technology.

In Russia, the development of mineral deposits and the development of technologies for its processing took on an industrial scale only in the second half of the 19th century.To date, work is underway in Siberia to produce this mineral in mines that are on the list of the largest in the world. At the same time, all types of diamond processing have been mastered.

Processing Features

The processing technology and the set of technical devices suitable for this is determined by the name of the final goal for which the processed diamond will be used.

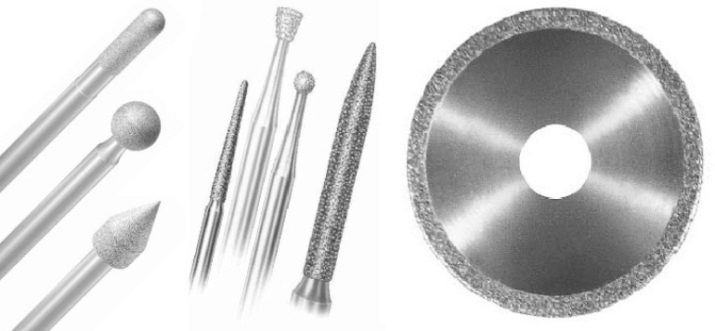

The characteristics of diamond determine the need for its use in various technological systems, tools and devices. For example, a fine diamond fraction - crumbs, is used as a spray coating that covers the working surfaces of any cutting devices. Diamond spraying is used for application on cutting discs, saws, bands designed for sawing metal, stone, concrete, ceramics and other materials.

Despite the resistance of diamond to the effects of destructive loads of a wide spectrum, it is fragile material. The use of shock-pressing technology allows you to grind diamonds into crumbs. Mineral crushing is carried out using a hydraulic press (this treatment option is rarely applicable).

More widely used rolling mill technology. As part of this process, raw materials are conveyed through a conveyor to a special chamber in which cylindrical rollers in contact with each other rotate. Passing between them, rough diamonds crumble. Considering the diamond strength factor, several blocks with rotating rollers having different sizes of the gap between them are used on the conveyor. This allows you to reduce the load on the mechanism, since stage-by-stage crushing is performed according to the principle from larger to smaller.

The working surface of the rollers is coated with diamond spraying, since no other material is able to withstand this load in such an effective equivalent.

The size parameters of the crumb fraction are determined by the name of the final goal for which it will be used. Coarse-grained diamond chips are used for rough processing of materials with a high coefficient of strength: ceramics, granite, porcelain stoneware. For example, coarse chips are used as a cutting element applied to the working edge of circular crowns designed for cutting round holes in solid materials: ceramic tile, concrete, granite slabs and others.

Diamond crumb of finer granularity is used to carry out fine processing of certain materials. As part of this treatment, the materials are cleaned, ground, polished. Polishing is done with a special paste, which is based on diamond dust. Obtaining diamond chips of different grain sizes is achieved by crushing and subsequent sieving.

Passing crushed diamond through mesh panels with different cell sizes allows fractions of a fixed diameter to be obtained.

The process of obtaining diamond materials suitable for industrial use is a more time-consuming procedure than the impact-pressing technology. As these materials are used, for example, circles for cutting glass, tips of turning tools and others. They are elements made entirely of diamond mass. The manufacture of such additions involves the implementation of production procedures associated with resource costs and the application of several processing technologies at the same time.

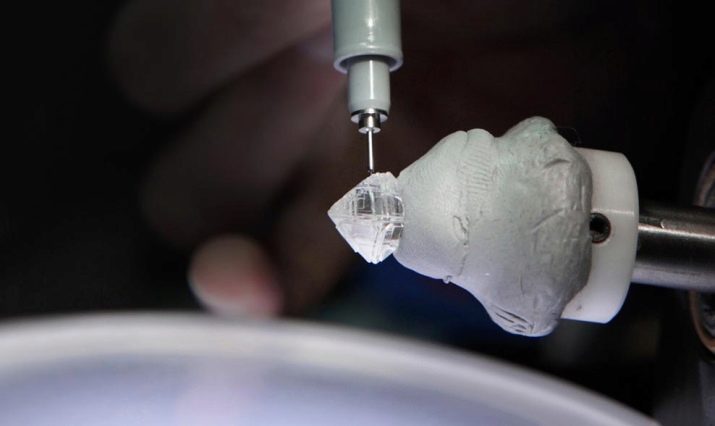

The strength properties of diamond greatly complicate the manufacture of parts that place high demands on dimensional parameters and accuracy of shape.

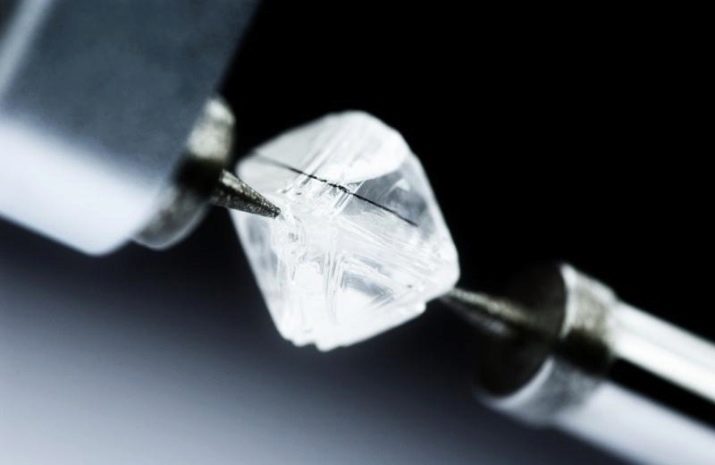

The only material that can be used to efficiently process rough diamonds is diamond itself.

The correct combination of factors affecting the processing tool and the material being processed allows processing to be performed as efficiently as possible. For example, in some cases, the workpiece to be heated is heated within the middle temperature range, and the temperature of the processing tool is kept in the low thermal range. In this case, the heated workpiece is amenable to processing, and the percentage of tool wear is reduced.

The use of this method is due to the properties of diamond, which it acquires under the influence of high temperatures. The higher the temperature, the lower the coefficient of mineral strength.

How to make a split?

Another method for processing diamond is hot iron processing. This mineral is able to enter into a chemical reaction with a metal heated to high temperatures. Hot iron begins to absorb the carbon component of diamond. At the point of contact between the red-hot metal and the mineral, the latter melts at the molecular level.

This method has low production efficiency, however, only with its help it is possible to achieve certain results in the processing of diamond material.

The use of the hot steel method is carried out when it is necessary to saw a large volume of raw materials with a minimum waste factor. As part of this method, a heated steel wire is used, driven by rotating shafts. In this case, the cut line is as thin as possible, and the loss of the main raw material is minimized.

Using the hot sawing method, only manipulations aimed at processing a general character can be performed. Detailed cutting is carried out using more sophisticated grinding technologies. Within the framework of this method, hot drilling technology is also used. In this case, the drilling steel element is also heated to high temperatures. The effectiveness of the method is increased by heating both parts as a result of friction against each other.

Diamond drilling is used to perform roughing. Holes of the desired diameter are drilled along the split line of the workpiece. Special anchor expanders are immersed in them. The technology allows you to manage the expansion of anchors alternately or simultaneously. Due to this, it becomes possible to perform a controlled split of the workpiece along a given line.

The key to the effectiveness of the method is played by the angle at which holes are drilled. Any deviation from the set values may lead to a violation of the accuracy of splitting.

How to polish a diamond?

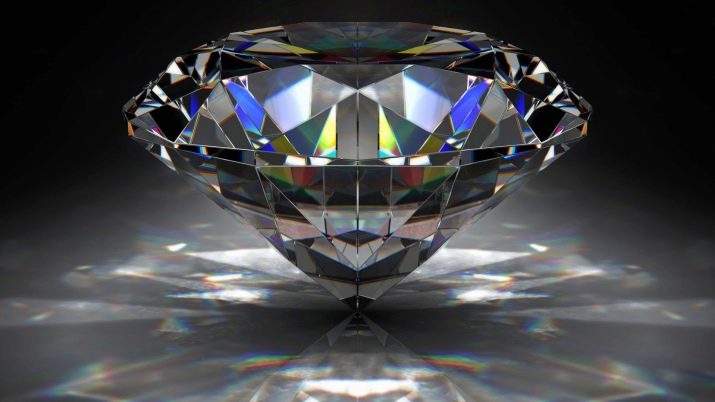

The main direction in the processing technology of this mineral is its grinding. Thanks to this procedure, diamonds acquire their final shape, and in some cases turn into gems.

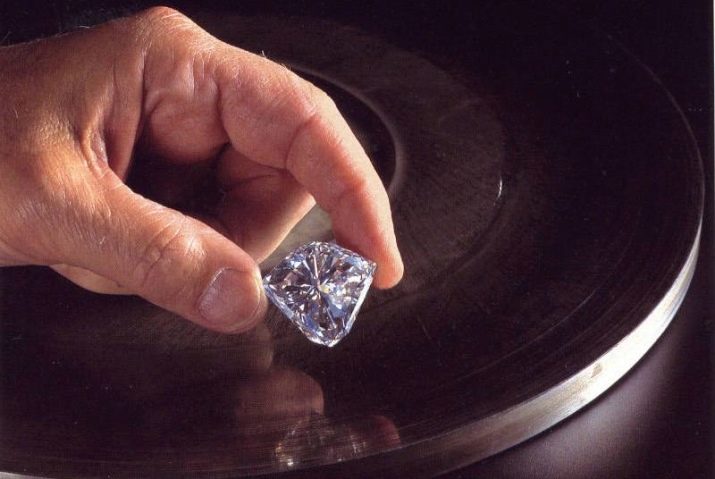

Making diamonds, craftsmen resort to phased processing methods. The rough blank is cleaned of impurities of other minerals, if any. Then a rough sawing is made, thanks to which the main shape of the future product is formed. After that, the cut begins.

To polish a diamond mineral, devices are used that are equipped with special nozzles - discs or plates having a thickness, shape, and material of manufacture corresponding to the name of the procedure being performed. On the working surfaces of these nozzles fractions of diamond chips of various diameters are applied.

If the cut is made in order to obtain a precious stone - a diamond, then many nozzles with a wide range of dimensional parameters are used. The first to use are plates or discs with the largest diameter diamond chips. As the process proceeds, the granularity of the nozzles decreases. Final polishing is carried out using diamond nanoparticles.

The tools with which the cut is made differ in their intended purpose and principle of operation. Some of them function due to the presence of rotational movement of the rotor, on the end shaft of which a grinding disk is attached. The work of other tools is based on the principle of reciprocating motion. Sanding plates are inserted into special clamps of these tools.

During processing, the diamonds are ground to a transparent glassy state. Due to the fact that the facets of the future diamond are located in strictly calibrated positions, and at a given angle, the rough raw material is transformed into a gem. At the last stage of processing, it is polished to a mirror state.

The reproduction of the whole process takes a huge amount of time (sometimes years), which is explained by the resistance of the mineral to external influences.

Interesting information on diamond mining and processing can be found in the next video.