Hand-made things, the so-called hand-made, have always been appreciated and appreciated by people who respect art. They are distinguished by the creativity of the idea, the uniqueness of execution and the scrupulousness of details.

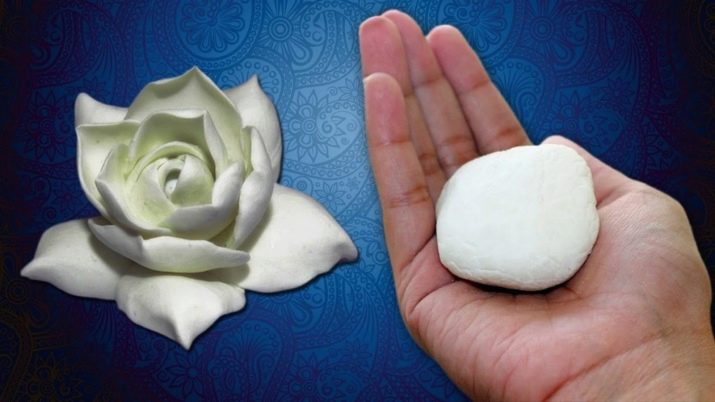

There are many materials that allow you to create masterpieces. One of these attractive new products on the market is cold china.

What it is?

Cold porcelain is an amazing material for creativity. Thanks to its properties, it makes it possible to make a variety of decorative elements: from massive and rough to the tiniest and most sophisticated.

It’s worth saying right away that there is no need to look for analogies of this mass with classical porcelain and ceramics. You will not find them. Cold porcelain has nothing to do with its classic version.

The only similarity is the appearance of the "impostor." When solidified in color, it slightly resembles real porcelain, which has undergone firing in an oven at a temperature of 1300 ° C. Cold porcelain products are not fired. They dry on their own, in the air becoming solid and durable.

In scientific terms, cold porcelain is a polymer mass for modeling and modeling. It is called polymer because it combines both natural and synthetic components. The initial composition of the material included corn starch, which is why it is also called Pasta di mais - corn dough or pasta, as well as glue, vegetable oil and glycerin. But modern craftsmen do not cease to supplement it with other ingredients to improve quality and expand the capabilities of the mass.

The finished product can be purchased at the store, but still it is better to make it yourself. So you can adjust its density, customizing it for your product, and you can always prepare the required amount of material.

Cold porcelain is an affordable tool for the embodiment of creative ideas both materially and practically.

The cost of the finished mass is low. And if you knead it yourself, then these minimum costs can be reduced.

By its consistency, cold porcelain resembles plasticine. But working with corn dough is much more pleasant: it does not get your hands dirty and is more convenient to sculpt. Children love to create from it. At the same time, mothers should not worry about the cleanliness of the workplace of the baby.

History of occurrence

The history of the material begins in the 19th century. Argentina is considered his homeland. Although there are other data, according to which this type of porcelain was developed by the Russian master Pyotr Ulyanovich Ivanov. It was established that while working at the St. Petersburg Imperial Porcelain Factory, he created floral compositions in white colors from cold porcelain at the beginning of the 19th century. They were used in the perfume industry, decorating them with perfume bottles. Decorated with them and fireplaces, mirrors, vases.

To this day, only about 10 of his works have survived, distinguished by originality and originality. The recipe for the unique composition of the porcelain mixture was lost after the death of the artist, and the secret of the unique plasticity and flexibility of Ivanovo porcelain was not unraveled. Until now, no one can revive the subtlety and elegance of the technique of Peter Ivanov.

However, in 2002, art master Evgeny Andreev invented his recipe for making porcelain. She has good ductility and is quite obedient to modeling. His works can be seen in the State Russian Museum and the salon-shop of the State Hermitage.

The properties

The structure of cold porcelain is compared with plasticine. It is just as soft, plastic, flexible, but does not stick to your hands and does not leave a greasy coating. When a cold porcelain figure is formed, after a while it freezes. To do this, she will need from 1 to 5 days. It all depends on the thickness of the material. This gives it strength, stability and durability. On the other hand, a sufficiently long solidification period makes it possible to correct the disadvantages.

Cold porcelain is a very malleable material, it allows you to sculpt the most ornate products.

It is absolutely safe for the health of both adults and children, and does not require specific skills in handling.

It is very convenient to use, working with it is easy and fun. According to the standard recipe, a product made of porcelain is obtained transparent, with a gray or yellowish tint. But even at home, the mass can be made colored. To do this, during cooking, liquid food coloring is added to it. However, sometimes it turns out too bright unnatural shade.

To give the product the desired color, it is better to colorize it in a finished form. In addition, all paints perfectly fall on cold porcelain. Although it is recommended to use acrylic or oily.

This material, of course, is not without flaws, but adhering to all the recommendations in the work and preserving your masterpieces, they will become nothing to you.

The first thing you should pay attention to is that cold porcelain is afraid of water.

It quickly absorbs moisture and softens, and the product itself can be deformed. Therefore, it is not recommended to store it in a room with high humidity.

Porcelain of this kind is sensitive to too high and low temperatures.

therefore it is advisable to protect it from direct sunlight. And it is not recommended to put the prepared mass before molding in the refrigerator, otherwise cracks will form on it. To extend the shelf life of cold porcelain figurines, it is varnished.This protects it from moisture and the sun and adds aesthetics in appearance, giving shine.

What can cold porcelain be made of?

The primary source of cold porcelain composition is a recipe containing corn starch, glue, glycerin and vegetable oil. This formula was presented to us by the ancient Argentines. Modern masters depart from this standard, making their own adjustments in order to improve the properties of the mass.

The modern classic recipe for this material includes starch, glue, glycerin and cream. 2 methods of its preparation are applied: boiling and kneading.

For the first option you will need:

- PVA glue - 1 cup;

- potato starch - 1 cup;

- glycerin - 2 tbsp. l .;

- baby cream - 1 tbsp. l

Mix glue and cream, put the mass on medium heat. Add glycerin while stirring the mixture.

Do not use aluminum cookware.

Gradually introduce starch, constantly mixing the mass. The degree of formation of the finished mass: cottage cheese - mashed potatoes - a lump of dough. Then we remove the mixture from the container (carefully, since it is hot), knead with the hands to the consistency of plasticine.

Another option.

Mix 1 tbsp. l Vaseline and 2 tbsp. l starch. Add 1/2 tsp. soda and PVA glue in the amount of 2 tsp. Knead until smooth. Lubricate hands with petroleum jelly or cream.

It should be noted that in the preparation of porcelain mass it is worth paying attention to the glue, which should be of high quality, and starch.

Starch can be used in different ways: potato, corn, rice, wheat, amylopectin, etc. It is important to consider that the grains of each type of starch are not the same in size and the temperature of their transformation into paste is also different. Potato starch has the largest grains, and the gelatinization temperature is lower, that is, it is necessary to choose the correct temperature regime for different products. Also, for example, potato starch requires more liquid, more precisely, glue.

The color of the mass depends on which starch you use. It can turn out white, yellowish or with a gray shade. Potato starch gives the highest transparency and snow-white color. From wheat starch, the mass is very supple, tender and soft, elastic and ductile. By color, it also turns white, but not snow-white, as in the previous case. Rice starch will give your product a beautiful milky tint, but it does not have transparency at all. A mixture of corn starch is also opaque and milky, but very flexible and obedient.

There are a lot of recipes for making cold porcelain at home. During the creative and experimental process, each artist discovers new subtleties that can improve the quality of the mixture.

Comparison with polymer clay

Along with cold porcelain, polymer clay has gained no less popularity. Although many masters reckon cold porcelain to it. Without finding fault with the classification, let us say that polymer clay is of several types. With one of them - cold porcelain, we already had the honor of meeting you.

A completely different, different from the previous one, is a type of polymer clay called thermoplastic. It is based on polyvinyl chloride and a plasticizer.

The main difference between this type of clay and porcelain is the need for baking.

In its raw form, thermoplastic is similar to plasticine. It will remain so until it is heat-treated. In domestic conditions, such a treatment becomes an ordinary oven. At the same time, it is important to choose the correct temperature regime so as not to dry the product, but at the same time bake it evenly.

Unlike porcelain, thermoplastic itself does not harden, that is, before baking, it remains soft and can be given any shape. After hardening, it becomes moisture- and heat-resistant, quite durable, which is an indisputable advantage.

The disadvantage of this material is the need for baking.

After this, it is necessary to thoroughly wash the oven, since cooking does not tolerate traces of thermoplastics in it. According to expert estimates, thermoplastic emits toxic substances when heated, which cannot be combined with products. Yes, and for the respiratory system, it is also dangerous.

If cold porcelain is primarily used to create realistic colors, then thermoplastic for this role is better not to use. As a rule, thin petals from it are very fragile and easily break or crumble.

I would like to focus on another type of polymer clay, this time self-hardening. It will be about cellulose or marshmallow clay. Thanks to the cellulose in the composition, the material has a very beautiful, thin, refined texture, to the touch really resembling marshmallows or velvet.

It, like porcelain, is used in polymer floristry (simply put, when forming flowers), but a special technique is used for this: the petals are rolled out with a finger in the palm of the hand and then dry themselves in the air.

The difference between porcelain and cellulose clay is to create flowers. Factory-made cold porcelain is sold in one color - white, and requires staining with paints. Clay is sold in several colors: white, black, brown, red, blue, yellow and green. Intermediate shades are obtained by mixing the primary colors.

It should be noted that cellulose clay has a rather high price compared to porcelain and thermoplastic.

Product Ideas

Cold porcelain is considered a universal material. Thanks to its flexibility and plasticity, anything can be created from it.

First of all, it is used to create realistic colors. They really come out as living. Using the material, it is possible to recreate even the smallest petal with all its curls, bends and subtleties. Such flowers are used as separate compositions, as well as in the form of decor. They are framed with hairpins, hoops, caskets, photo frames, cabinets, dishes.

From cold porcelain, various crafts are made in the form of figurines of people, animals, magnets. Incidentally, wedding cake is also decorated with such inedible figurines in the form of a bride and groom.

From porcelain mass it is possible to create creative jewelry: beads, earrings, rings, bracelets, brooches, or interior decor: vases, candlesticks, panels, napkin rings. Parts of dolls are made from this kind of porcelain.

Cold porcelain is an excellent material for decorative sculpting. In working with him, the main thing that you have to work hard on is your imagination. Everything else will turn out incredibly easy and simple.

In the next video, you can get acquainted with the process of creating roses from cold porcelain.