Nowadays, more and more people decide to warm their balconies. This is not surprising, since the glazed balcony increases the usable space, allows you to expand the active functional area, which can be used as a game room, a place of rest, an office or even a bedroom. Among our compatriots there is an opinion that aluminum balcony glazing differs from plastic only at a price. But this is not so - the profile has many other advantages. It is about them that will be discussed in our article.

Features

To begin with, let us dwell on the fundamental differences between metal and traditional plastic balcony structures. To do this, we will examine in more detail the operational characteristics of each of the options. Plastic blocks are made of the same materials from which plastic windows are made. Such options are most often called "warm" glazing. These designs have high sound and thermal insulation parameters, but they are quite massive. It is impossible to install them in the "Khrushchevs" and structures of the old building - there is a very high risk that the balcony flooring simply can not withstand the profile dimensions.

For such houses, the best option would be aluminum glazing. In 80% of cases it is cold, therefore in winter such a balcony can be used exclusively as a pantry.

And yet even such a lightweight design can protect living rooms from dust and extraneous noise.

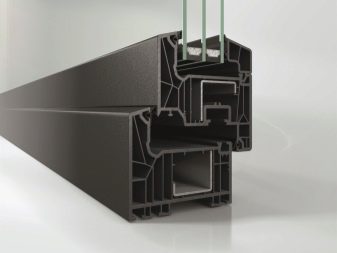

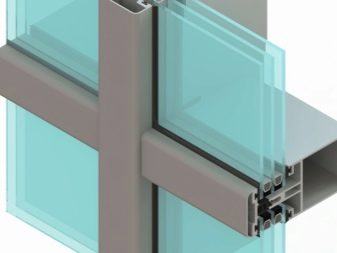

The remaining 20% falls on “warm” aluminum glazing, when the balcony can be used as a full-fledged living space. For this, special double-glazed windows are used. The aluminum profile in them consists of three main layers:

- outer layer of metal;

- insert thermostat, which is designed to break the bridge of cold;

- inner metal layer.

In factory conditions, the aluminum profile is usually insulated with reinforced fiberglass, foamed materials or polyamide.

The main advantage of loggias of this type is a reduced level of thermal conductivity, but in terms of cost, such a design will cost much more than plastic, so this option is practically not used in everyday life.

Advantages and disadvantages

Glazing from aluminum profile has been used for quite some time. In modern designs, the metal is additionally coated with a polymer composition, due to which the working life of the entire structure and the supporting frame is significantly increased.

The main advantages of aluminum glazing are due to the physical and operational parameters of the metal itself.

- Aluminum is a strong metal, as a result, the narthex between the wings and the window frame becomes especially dense. Thus, the adjustment of fittings will be required only after prolonged use of the frame.

- Like most other metals, aluminum is oxidized, but in the case of a metal profile, this process practically stops due to the application of a polymer coating, which reliably protects the material from rust, and also makes the appearance of the structure more attractive.

- The aluminum profile coated with polymers is resistant to ultraviolet rays. It does not lose its functional characteristics under the influence of precipitation and temperature fluctuations.

- Maintenance of aluminum frames assembled from a metal profile does not require effort on the part of users.

- Glazing with aluminum blocks is considered the most affordable, since its price is much lower than the cost of wooden and plastic systems.

- Installation of double-glazed windows from aluminum is simple. Any home master can do it with their own hands - for this it is enough just to purchase the design in an already finished form.

It would seem that double-glazed windows installed using an aluminum profile are practical and inexpensive. However, they are not very popular. The reason is that they have one very significant drawback - the high thermal conductivity of the metal. In other words, their use makes sense only when arranging a cold balcony, since the temperature on it will hardly differ from the temperature of the air outside.

"Cold" glazing has significant advantages.

- Affordable price - glazing with lightweight aluminum material costs 2-3 times cheaper than installing standard PVC frames. In addition, when installing the blocks there is no need for additional work related to the overhaul of the balcony slab and reinforcement of the parapet.

- "Cold" glazing allows you to free up maximum area on the balcony. Lightweight structures can always be carried a little 20-30 cm, thereby increasing the functional area of the balcony by about 1 square. m

- Aluminum is not so sensitive to external temperature fluctuations and deformations arising under the influence of strong wind loads.

- Aluminum balcony systems are guaranteed to work even after decades.

Warm warming of loggias with an aluminum profile is not so common. Firstly, it is much more expensive than the “cold” one. The user will have to pay a high price both for the material itself and for its installation.Secondly, the insulated structure “eats” the free area of the balcony, as a result you get not a full-fledged functional area, but simply a matchbox.

Nevertheless, “warm” glazing has its advantages:

- good thermal insulation is ensured by a 3–6 mm thick double-glazed window; such windows are optimal for installation in harsh climates;

- thanks to the insert, which separates the inner and outer walls, the cold is not transmitted to the room, and the heat does not go out;

- a balcony insulated with an aluminum profile can easily be turned into a continuation of the room;

- the design has enhanced soundproofing properties - no extraneous sounds will bother you even if you live near a busy highway or airport;

- windows made of aluminum profile are much stronger than window blocks made of any other PVC material, due to which you can always install glazing from the ceiling to the floor, without fear of curvature of the frame when operating in conditions of high wind loads.

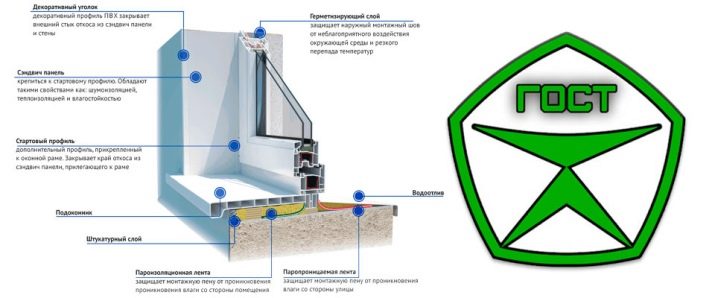

In order for balcony aluminum glazing to fulfill all its functions, Give preference to models made in strict accordance with existing regulations.

In matters of quality of aluminum profiles, manufacturers are guided by the standards GOST 21519-2003 and GOST 22233-2001.

Kinds

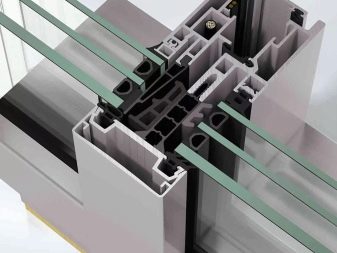

Aluminum blocks installed on balconies and loggias can be frame or frameless. Frameless glazing allows you to make the interior of the balcony as lit as possible, and from the outside it looks very modern and stylish: the profile here has a small width, so the effect of solid glass is created. In addition, frameless glazing allows maximum preservation of the interior space of the balcony.

The pluses of such designs include the fact that hardened material is used during assembly - it is almost impossible to break such glass, for this it will have to be beaten with a hammer. And even if for some reason it breaks, then users will not be able to cut themselves, because with a strong blow the hardened material will simply crumble, leaving no protruding fragments in the openings.

However, frameless glazing has its drawbacks, namely:

- good visibility of the interior contents of the balcony from the street;

- lack of installation of mosquito nets in the summer;

- lack of absolute tightness;

- worse than traditional construction, delays noise from the street;

- the inability to equip a warm balcony.

Obviously, the number of disadvantages significantly outweighs the number of advantages, so in most cases, the owners of residential premises still prefer to install frame systems on balconies. They look very impressive, are lightweight and easy to install and, if necessary, insulate additional space, are optimal for balconies with a roof.

In terms of tightness, frame aluminum systems will still be slightly inferior to plastic ones, but despite this, they protect the room from noise and cold much better than frameless ones.

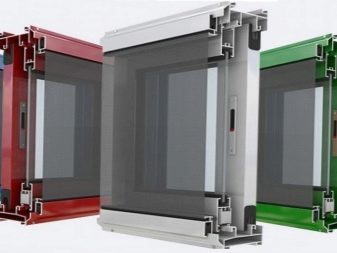

Frame colors

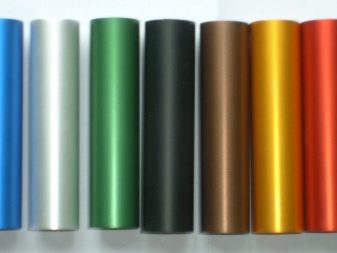

One of the advantages of installing aluminum frames is the ability to paint them depending on the user's preferences and interior features. Painting is carried out by one of the following methods.

- Anodizing. In this case, at the output, the frame acquires a color with a pronounced metallic tint. This effect is a consequence of the formation of the oxide layer. It creates protection on the surface of the metal, protecting it from rust.

- Powder staining. Profiles treated in this way are more resistant to corrosion and deformation, since such a coating dries under the influence of elevated temperatures.The powder coating during operation does not peel off, does not crack in frost, and under the influence of direct ultraviolet rays retains its tone. However, such processing is possible only in a production environment; it is impossible to paint a house.

- Lamination This method is a bit like coating PVC blocks with all kinds of films. This is the best way to bring the loggia into uniformity with the overall stylistic and color scheme of the interior.

Aluminum windows in the interior of the balcony

The appearance of metal frames in the interior of the balcony largely depends on the profile, the total number of window openings, as well as the number of flaps to open. For example, when installing remote structures with sewn ends, a rectangular block is usually used with window openings located in a single plane. If you intend to completely glaze the balcony outside with a stove - in this case the block will be U-shaped. For any corner balcony, the frame must have an appropriate number of kinks. Depending on the method of opening, the movable flaps of the system can be made in several versions:

- standard swing - they usually open on rotary hinges in one direction or another;

- folding - open by analogy with the window, that is, from top to bottom;

- combined option - in this version, within the framework of a single design, options are provided for both standard swing and tilt opening.

Sliding sashes are especially popular among buyers - they move to the sides according to the sliding wardrobe mechanism along the rails installed from above and below, thereby opening the opening. This option is interesting due to the possibility of using the already cramped space of the balcony as ergonomically as possible.

Review Reviews

Nowadays, it’s not so easy to figure out which version of glazing users consider the most successful for their houses and apartments. The opinions of the owners and their many reviews vary greatly. Analyzing all the information presented on thematic sites, the following points can be highlighted:

- according to consumers, plastic blocks are more massive and overall in comparison with systems made of aluminum profile;

- plastic, unlike metal, is not resistant to mechanical damage;

- aluminum frames do not retain heat well and in this regard they lose significantly with plastic.

It is these characteristic features that need to be considered before choosing the appropriate glazing method for your balcony. Each of them has its pros and cons, therefore, first of all, it is necessary to study the technical condition of the balcony, the need for its additional strengthening and strengthening of the parapet. An important role in choosing a glazing method is played by the planned use of the additional room and the total area of the loggia in use.

Manufacturers

Today, aluminum profiles are in demand on the market, so many companies offer this kind of design. Among the variety of models presented, users single out several manufacturers whose products are of high quality, practicality and durability.

- Schuco. German company offering one of the highest quality products. Aluminum profiles of this brand are characterized by a special strength and unique technical and operational parameters.

- New tex group. An Italian holding whose profiles users describe as the most durable and practical.

- Provedal. The aluminum profiles of this Spanish brand are always very popular among Russians. Experts mark them as reliable, lightweight and high quality material. Allowed to be used on balconies and loggias of all kinds.

How to care?

In conclusion, we give some recommendations on how to maintain the freshness and cleanliness of aluminum blocks on balconies. It is best to choose the means recommended by the window manufacturer for this. However, if they are not at hand, you can use any mild detergent compositions without abrasive components.

Aluminum frames are washed as they become dirty, but at least once every six months. If the installed profile has a protective polymer coating - it is best to consult your sales representative about the features of competent care for him.

Any minor defects and scratches that occur during operation can be corrected using special correctors. With a significant area of damage, the restoration of the coating is carried out using pastes based on aluminum.

Separate care requires accessories. Hinges, guide rollers, and moving parts occasionally require cleaning and lubrication.

The overall tightness of the installed window system largely depends on the integrity of the sealant, so it needs to be changed as it wears out. To do this, select the same material or its corresponding thickness.

According to user reviews of window structures made of aluminum profile, with proper care, the aesthetics of the glazed frame and its functional characteristics will remain unchanged for many years.

Good examples

In recent years, aluminum profile blocks for loggias and balconies have become increasingly popular, as the material is characterized not only by increased strength parameters, but also by its original design.

Frameless glazing is very light and simple, while it looks spectacular from the outside, and inside you can install a window from floor to ceiling.

Frame blocks are more functional, they better protect additional space from noise, wind and cold, and with a quality finish of the balcony they turn it into a stylish functional space.

About the features of glazing balconies with aluminum profiles, see below.