Samp for an aquarium is a unique set of equipment to maintain the required parameters of the aquatic environment. Its difference from the well-known set of aquarium devices (spray-aerator, filter, heater) is that it combines all the useful properties of these devices.

What it is?

This external device, often called a technical aquarium, completely freeing the internal volume of the aquarium from any technical elements, which significantly increases the useful volume, does not interfere with the observation of the inhabitants and, of course, significantly increases the decorative properties of an artificial reservoir. Samp also allows you to increase the real volume of the aquarium without a visible increase in size, since it constantly receives water from the main tank. Externally, this device is a smaller aquarium with several partitions.

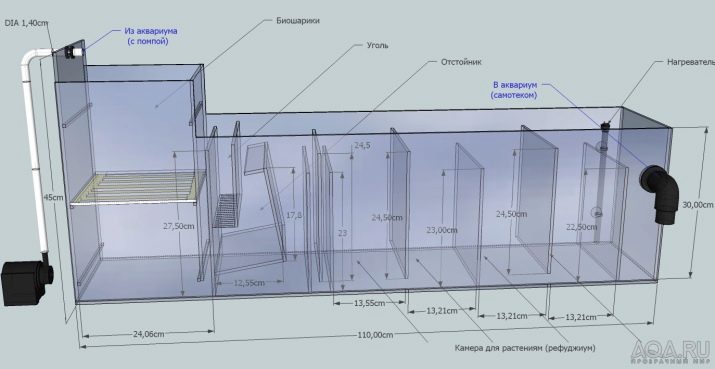

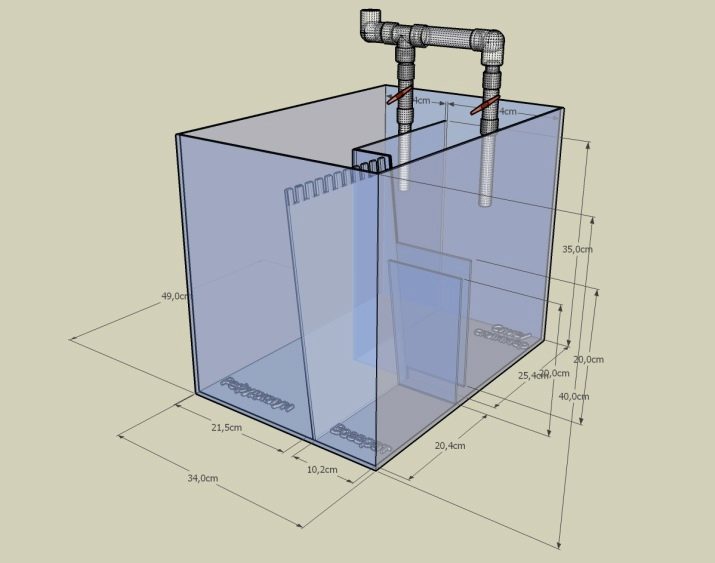

The circuitry of this complex device is actually simple.

- The intake of water from the aquarium through the nozzle is equipped with a nozzle with a mesh-filter that prevents parts of plants or animals (for example, fry) from entering the sump.

- Mechanical filtration is carried out in the first compartment with the help of porous materials (foam rubber, mineral wool, synthetic winterizer, etc.) and allows you to separate coarse impurities that create turbidity (dusty soil particles, minute sludge, etc.).

- In the next compartment, biological treatment is carried out with the help of bacteria developing in porous materials (expanded clay, pumice, etc.).

- Then the purified water is heated using an aquarium heater to the desired temperature.

- In the last compartment is a pump that pumps purified water back into the aquarium.

- Water discharge is equipped with an aeration system, water is saturated with atmospheric gases (oxygen and carbon dioxide).

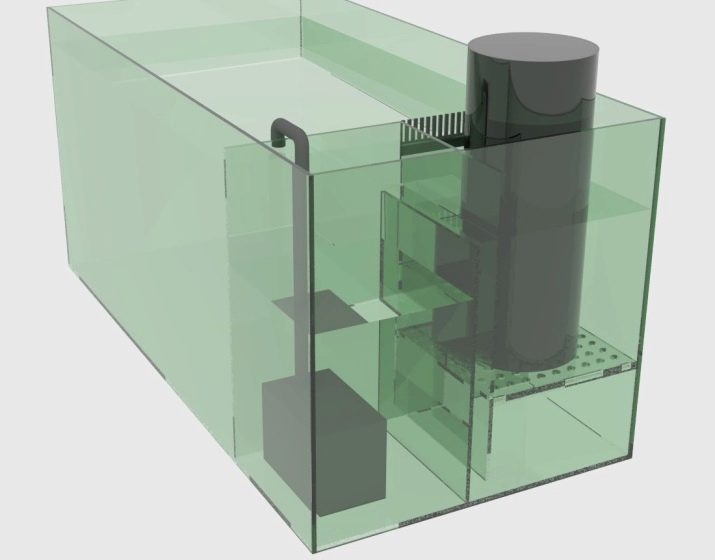

The scheme can be more complicated, for example, a so-called foam column can be added to trap organic residues in the form of foam. It is also possible to equip a compartment with absorbent material, in which neutralization of various kinds of toxins, including nitrogen-containing decomposition products of organics, is neutralized. For deeper cleaning, an ultraviolet lamp designed to kill bacteria can also be added to the circuit. The deepest cleaning, of course, can be created in large multi-section sumps, usually arranged for aquariums with a volume of more than 500 liters.

The water level in the sump is maintained thanks to a control valve mounted on the inlet hose. Water from the main reservoir is fed by gravity, which is why the device is placed under the aquarium.

Hence, in fact, the name is sump, this term in English-speaking countries is called the sump of the internal combustion engine - the crankcase, in which the used oil is accumulated for its subsequent discharge. The pump integrated in the aquarium sump circuit delivers purified and heated water back to the aquarium.

The weak link in the design remains precisely the gravity flow of water. In the event of a power outage, the pump stops working. Then part of the water from the aquarium can completely pour out through the sump. This moment is regulated by insignificant immersion of the supply hose to a depth of not more than 1 cm. In this case, relatively little water will leak when the pump is turned off.

One solution to the problem is the back technical aquarium connected to the main one according to the principle of communicating vessels. Position it behind the main reservoir, so that it is hidden from the eyes of observers. If there is enough space behind the main reservoir, and access to this space is not difficult, this arrangement can be considered optimal.

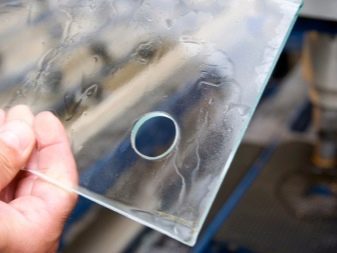

The flow of water from compartment to compartment is due to the special arrangement of partitions. Water flows from the first compartment into the second from below, from the second to the third from above, and so on. Drilling glass allows you to change the scheme, arranging the flow of water into the first compartment from the bottom, this will help create a more efficient filtration.

The calculation of the size and volume of a technical aquarium is not so complicated. At least 10% of the water in the main aquarium should be placed in it, this will avoid overflowing the tank when the pump is switched off and overflowing the aquarium if the mesh-prefilter of the supply hose is clogged. The filling of the system compartments in working condition should occur no more than half.

A volume reserve is needed just in case of accidents, so that water flowing from all hoses and from the surface of the aquarium can fit in the sump. Home-made systems are often limited only by the size of the cabinet in which they are placed.

The efficiency of the sump system in many respects depends not so much on the volume as on the rate of water exchange, that is, on the power of the pump. However, one should not forget that pumping a large volume of water through a small amount of active elements, their effectiveness will soon be lost. A normally operating sump must be cleaned from accumulated dirt approximately every six months. This is the optimal mode of operation of the device. After deep cleaning and replacement of active elements, at least a month should pass before the start of all biochemical processes for which an external cleaning system is created.

If the additional volume of the cabinet is limited, or the aquarium is very large, part of its volume can be allocated for the built-in sump. Such a solution may be simpler, since there is no need to adjust the speed of water supply and pumping. For such a system, it is necessary to separate at least 10 cm of the width of the aquarium.

The most technically simple solution is to arrange a technical compartment by separating it from the main aquarium with a vertical partition.Further arrangement is no different from equipping an external technical aquarium.

Ready Samps

Companies whose specialization was aquarium equipment, of course, did not disregard such effective devices as sumps. The capabilities of finished devices are often limited by filtration, biological treatment and aeration. However, the equipment manufactured by these companies allows you to complement the set of functions of sumps, for example, by heating water or chemical filters. A fairly wide selection of such products of relatively small volume is offered by Chinese manufacturers.

In large pet shops specializing in accessories for aquariums, you can buy technical aquariums from well-known European manufacturers.

Often on sale there are components necessary for the installation of the sump, for example, glass with drilled holes and a pump or hose mounted in them.

Some Russian firms make technical aquariums to order - both for saltwater and freshwater aquariums. Their experts can also recommend device layout options. The size of the can is selected in accordance with the wishes of the customer. Companies offer ready-made aquariums with pedestals and sump systems Aquarium systems and Arcadia. Technical aquariums are developed and manufactured by a St. Petersburg company Coralreef-aqua, specializing in saltwater aquariums.

DIY samp

Like many equipment, aquarists often make sampas themselves. The most difficult operation is considered the need for drilling glass for mounting pipes. If there is no experience in this matter, you can spoil more than one glass. You need to drill with a special diamond nozzle, at low revolutions of the drill constantly wetting the drilling site with water and observing the perpendicular arrangement of the drill with respect to the glass.

To make a sump, you can use a ready-made aquarium. In it, using a special aquarium silicone sealant, transparent glass partitions are arranged, the task of which is to divide the technical aquarium into compartments.

First, it is better to design the future sump, deciding in advance what functions it will perform. It is clear that the more there are, the more compartments will have to be arranged.

It must be remembered that reducing the width of the compartments to less than 10 cm is undesirable, this may be the main limitation when installing the sump in a finished aquarium. Partitions should be mounted gradually, one after the other, waiting for the sealant to completely dry. If a technical aquarium is specially made, then one of the limiting factors may be the size of the cabinet or rack where it is planned to be installed. Filling the compartments of the finished sump is usually not difficult, since all components are quite affordable, you can buy them in the appropriate stores.

Next, see how to make a samp yourself.